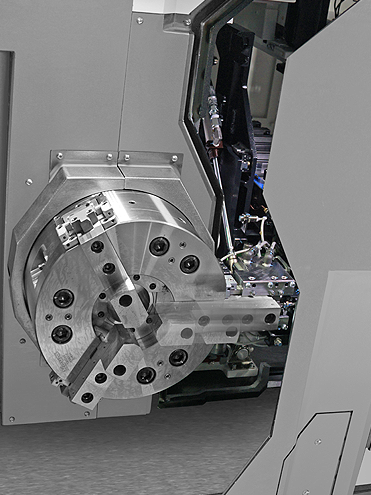

INTEGREX i-450H ST

Photo with optional equipment

MACHINE DESCRIPTION:

The INTEGREX i-450H ST Multi-Tasking Center delivers the highest level of single-setup part-production versatility with the combined processing power of a turning center and full-function machining center. This machine configuration features a second turning spindle (S) for DONE IN ONE® machining and a lower turret (T) with optional rotary tool capabilities, minimizing fixtures, tools, handling and non-cut time.

The machine enclosure, tool magazine and auto jaw changer have all been designed to accommodate a comprehensive range of automation technologies, including gantry loaders, bar feeders and articulating robots. And thanks to the power of its MAZATROL SmoothAi CNC, the INTEGREX i-450H ST offers standard specialized operations such as crank shaft inclined drilling or gear skiving.

LOWER TURRET

Manufacturers can achieve increased productivity with the use of balance cutting with the milling spindle and lower turret for simultaneous machining with two tools.

STANDARD LOWER TURRET SPECIFICATIONS

A 12-position drum turret enables extended machining operations.

|

LOWER TURRET WITH ROTARY TOOLS (OPTION)

The optional rotary tool functionality for the lower turret allows for machining using the lower turret and the milling spindle simultaneously for improved productivity.

|

AUTOMATION

BAR FEEDER

With a bar feeder and optional scheduling software, shops can easily manage both high-mix/low-volume production and high-volume production.

TURN ASSIST (TA)

Thanks to easy-to-use software, the RoboJob Turn Assist robot system does not require complicated teaching routines to achieve smooth, efficient movement for loading and unloading parts.

AUTO JAW CHANGER

Automatically change out jaws from 10-jaw stockers located on each spindle via program commands.

MACHINE CHARACTERISTICS:

- Main spindle with 4.4" bore accommodates bar material up to 4" in diameter

- 4,000 rpm, 35 hp second turning spindle (S) for DONE IN ONE operations

- Parallel-type 12-tool lower turret with optional 10,000 rpm, 7.5 hp rotary tool capabilities

- Next-generation MAZATROL SmoothAi CNC for the highest level of programming and production efficiency

- Automation-ready design accommodates bar feeders, articulating robots and more

- Front and rear tool setup with 38, 74 or 112-tool magazine and automatic tool changer

- Auto jaw changers with 10-jaw capacities located on each spindle

Machine Specifications

| Specification | Bed Length - 1500U mm | |

|---|---|---|

| Capacity | Maximum Swing | 26.38 in / 670 mm |

| Maximum Machining Diameter | 26.380 in / 670 mm | |

| Maximum Bar Work Capacity | 4.0 in / 102 mm | |

| Maximum Machining Length | 59.800 in / 1519 mm | |

| Main Spindle | Chuck Size | 12 in |

| Maximum Speed | 3300 rpm | |

| Motor Output (40 ED Rating) | 50 hp / 37 kw | |

| Second Spindle | Chuck Size | 10 in |

| Maximum Speed | 4000 rpm | |

| Motor Output (40 ED Rating) | 35 hp / 26 kw | |

| Milling Spindle | B-Axis Travel | 240° |

| Magazine Capacity | 38 | |

| Maximum Speed | 12000 rpm | |

| Motor Output (30 minute rating) | 32.0 hp / 24 kw | |

| Turret (Lower) | Number of Tools | 12 |

| Feed Axes | Travel (X Axis) | 27.36 in / 695 mm |

| Travel (X2 Axis) | 8.66 in / 220 mm | |

| Travel (Y Axis) | 11.81 in / 300 mm | |

| Travel (Z Axis) | 62.40 in / 1585 mm | |

| Travel (Z2 Axis) | 60.59 in / 1539 mm | |

| Travel (W Axis) | 60.59 in / 1539 mm | |