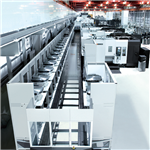

PALLETECH provides manufacturing flexibility and is efficient in both low- and high-volume production. It is available in a wide range of system layouts, including one, two and three level configurations. Furthermore, it is modular so you can easily add pallets as well as loading and wash stations – pacing your capital investment with the growth of your business. PALLETECH accommodates up to 16 machines, 6 to 240 pallets and as many as 8 loading stations. In fact, the benefits of our PALLETECH system are so great, we use it in our own manufacturing facilities.

AUTOMATION

What is PALLETECH?

The PALLETECH System is exclusive to Mazak and brings advanced, pre-engineered automation to today’s machining environments. It is a Multi-Tasking solution for any manufacturing or volume requirement, and is compatible with all of our horizontal machining centers and most of our vertical and 5-axis machining centers.

With our PALLETECH Manufacturing Cell controller software over standard PCs and networks, shop management can monitor operations, view and change schedules on-the-fly, manage part program files from anywhere on the network, track tool life/breakage and issue instructions to the shop floor. Users are able to interrupt a planned machining queue and produce an emergency part with no cost penalty.

Explore PALLETECH's Modular Flexibility

Why PALLETECH?

Smooth PMC

SMOOTH PMC software makes it easy to monitor a PALLETECH-based manufacturing cell from almost anywhere using a smart phone, PC or tablet. The software, which features a home screen with the same look and feel as the MAZATROL Smooth CNCs, also makes it possible to change schedules on the fly, manage part program files, track tool life/breakage as well as issue instructions to the shop floor.

PALLETECH Benefits

- Optimize your labor with one employee operating multiple machines

- Gain a competitive edge through unattended “lights out” operation

- Drastically improve your machine utilization

- Convenient expansion to quickly respond to growing production needs

- Give priority to last-minute jobs without reorganizing other work

- Increase pallet storage while taking up minimal floor space

- Gain the flexibility required for shorter product life cycles

- Reduce in-process inventory and accomplish just-in-time production

- Flexible and creative layouts can optimize manufacturing floor real estate

- Raw material storage option keeps materials in one convenient location near your operations

- Link two different types of Mazak machine tools together to make a fully automated manufacturing cell

Options:

- Tilting load stations

- Part wash stations

- Raw material storage

Quality Control

The PALLETECH is our own unique design and because we manufacture it ourselves, we can ensure balanced workpiece capacity with our machines. Before a PALLETECH installation takes place, we offer many of our customers free simulations to make sure the PALLETECH configuration they want has the capacity to meet their workflow requirements. As such, the PALLETECH has the highest number of successful installations of any pallet handling system on the market.

Contact your local Mazak Representative or visit one of our Technology Centers to identify what Mazak Machining Center best fits your part-processing needs.