History & Milestones

Over the years, Mazak has positioned itself as one of the world's most-recognized leaders in the manufacturing industry. To benefit its customers and revolutionize the global machine tool market, the company has invested in and expanded its operations over more than a century of history.

2021 - Present

Introduction of new INTEGREX i-H Series Multi-Tasking Machines.

MPower complete customer care program launches in North America.

Introduction of the SYNCREX Series of Swiss-style machines, designed and manufactured on the Mazak Corporation North American Headquarters campus.

MPower On-Demand Learning (MODL) system launches in North America with more than 100 multi-level courses available anytime, anywhere.

The Association of Manufacturing Technology (AMT) honors Brian Papke, former Chairman and now Executive Advisor to the Board of Mazak Corporation, with the Al Moore Award given to members of the manufacturing technology community who have demonstrated a lifetime of dedication to the industry.

Introduction in the U.S. of Mazak Capital Equipment Financing (MCEF).

2011 - 2020

Boeing honors Mazak with a Performance Excellence Award for superior supplier performance in 2010.

Mazak Corporation announces installation of a second V-140N 5-axis machining center in Florence, Kentucky. It features a 10 m table and three new laser FM systems.

Cincy magazine names Mazak Corporation a MANNY Award winner for manufacturing excellence and product innovation in Florence, Kentucky.

Houston (Southwest) Technology Center relocates and expands.

Chairman and CEO Teruyuki Yamazaki passes away.

Mazak Corporation begins exporting Kentucky-designed and built machines to Asia and South America.

The Southwest Regional Headquarters and Technology Center earns the Company of the Year award from the Greenspoint District near Houston, Texas.

Mazak receives the Northern Kentucky Chamber of Commerce Greater Cincinnati International Trade Award as a champion of global commerce.

Boeing honors Mazak with a Performance Excellence Award for superior supplier performance in 2011.

Expansion of the Florence, Kentucky manufacturing plant by 100,000 square feet announced.

Completion of the National Technology Center expansion in Florence, Kentucky. The National Service and Customer Training departments move into the now 100,000-square-foot facility.

The Tri-County Economic Development Corporation honors Mazak Corporation as one of its Thoroughbred Award winners for economic impact in Northern Kentucky.

The Cincinnati USA Partnership for Economic Development recognizes Mazak with its Growth Award for continuous investment in its manufacturing campus and the local area.

Cincy magazine names Mazak Corporation a two-time MANNY Award winner for manufacturing excellence and product innovation in Florence, Kentucky.

40th anniversary of Mazak Corporation production in the U.S.A.

In Florence, Kentucky, Mazak unveils the Mazak iSMART Factory™ concept, which focuses on free-flow data sharing and plant-wide connectivity. Mazak invests $30 million in the Kentucky manufacturing plant, including $19 million on capital equipment.

Introduction of the new SMOOTH TECHNOLOGY process-performance platform alongside the MAZATROL SmoothX CNC, dubbed the world's fastest.

Introduction of two HYBRID Multi-Tasking machines.

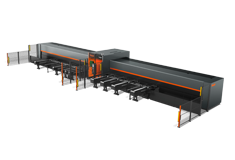

Mazak Corporation unveils a new powder coating line that speeds production by 74% in its Kentucky manufacturing plant.

MAZATROL Smooth CNCs gain new functions that allow Mazak's Multi-Tasking machines to perform gear hobbing and skiving operations. Mazak showcases a new four-step closed-loop production process for cost-effective machining of tight-tolerance gears in hours instead of days.

Mazak Corporation receives ISO 9001:2008 recertification of its Kentucky manufacturing plant and spindle rebuild operations.

Completion of the expansion of the manufacturing plant in Florence, Kentucky to 536,000 square feet, placing the North American Headquarters and manufacturing campus at a total of 800,000 square feet.

Introduction of the MAZATROL SmoothG and MAZATROL SmoothC CNCs.

In the U.S., Mazak Corporation develops Mazak SmartBox – a launch platform for easy and highly secure entrance into the Industrial Internet of Things (IIoT) – in conjunction with Cisco.

Introduction of the INTEGREX i-400 AM, Mazak's first HYBRID Multi-Tasking machine with additive capabilities.

Dallas Technical Center opens in the U.S.

Announcement of Yamazaki Mazak Inabe plant in Japan.

Brian Papke, long-time president of Mazak Corporation, accepts a new position as chairman.

Daniel Janka, former executive vice president, becomes company president.

Development of the VARIAXIS j-600 AM HYBRID Multi-Tasking machine, advancing the DONE IN ONE® concept with combined additive and subtractive manufacturing.

The Mazak iSMART Factory™ begins operation at the Yamazaki Mazak Headquarters in Japan.

Announcement of the integration of two production bases in Minokamo, Japan and the plan for the Mazak iSMART Factory™ at Minokamo.

The Preci facility opens in Querétaro, Mexico providing a new 6,000-square-foot home for service technicians and applications engineers trained to assist with the local aerospace and automotive industries.

Inabe plant in Inabe City, Mie Prefecture begins operation after completion of first stage of construction.

Brian Papke, chairman of Mazak Corporation, is inducted into the Northern Kentucky Business Hall of Fame.

Introduction of the Kentucky-designed and built VC-500A/5X AM HWD HYBRID Multi-Tasking machine with HOT WIRE technology developed in collaboration with Lincoln Electric to provide a high-speed additive solution with programmable welding automation and full 5-axis milling capabilities.

Development in Japan of the INTEGREX AG series of HYBRID Multi-Tasking machines with integrated gear cutting.

Development in Japan of the VARIAXIS j-600/5X AM HYBRID Multi-Tasking machine, integrating the world's first blue-laser additive manufacturing and machining.

Development in Japan of the SmoothAi spindle that uses artificial intelligence to minimize chatter for high-precision surfaces and higher productivity.

Yamazaki Mazak Corporation celebrates its 100th anniversary.

Tomohisa Yamazaki is appointed Chairman and CEO.

Takashi Yamazaki is appointed President.

Mazak Corporation wins the 2018 Top Plant Award from Plant Engineering magazine.

Northern California Technical Center opens in Fremont, California.

Development in Japan of the new INTEGREX i-H Series of Multi-Tasking machines.

Development in Japan of the next-generation MAZATROL SmoothAi CNC system with MAZATROL TWINS software.

Development in Japan of the VARIAXIS C-600 simultaneous 5-axis machining center.

The Yamazaki Mazak Museum of Machine Tools opens in Japan.

Mazak iSMART Factory™ in Minokamo, Japan begins operations after the integration of two production facilities.

Mazak Corporation launches All Axes podcast series.

New Spindle Rebuild Department opens in Mazak Corporation North American Headquarters.

Florida Technical Center opens in Orlando.

Edmonton Technical Centre opens in Ontario, Canada.

Development of the new MAZATROL SmoothEz CNC.

Development in Japan of the VARIAXIS i-800 NEO simultaneous 5-axis machining center.

Development in Japan of the HCN-6800 NEO horizontal machining center.

Development of the QT-Ez and VC-Ez Series machines.

Friction stir welding specialist Mazak MegaStir becomes part of Mazak Corporation.

2013 Completion of the Yamazaki Mazak Machine Tool (Liaoning) Co., Ltd. Plant.

2013 His Royal Highness The Prince of Wales visits Yamazaki Mazak's European headquarters.

2015 Introduction of the INTEGREX i-400 AM, Mazak's first HYBRID Multi-Tasking machine with additive capabilities.

2014, 2015Introduction of the new SMOOTH TECHNOLOGY process-performance platform and MAZATROL Smooth CNCs.

2016Setouchi Technology Center opens.

2016China Parts Center opens.

2016Development of the VARIAXIS j-600 AM HYBRID Multi-Tasking machine, combining additive and subtractive manufacturing.

2017 The Mazak iSMART Factory™ begins operation at the Yamazaki Mazak Headquarters in Japan.

2017 Development of the UD-400/5X high-speed, high-accuracy 5-axis machining center designed for molds and high-precision parts.

2018 Inabe plant in Inabe City, Mie Prefecture begins operation after completion of first stage of construction.

2018 Development of the INTEGREX AG series of HYBRID Multi-Tasking machines with integrated gear cutting.

2018 Development of the FG-220 DDL 3D direct diode laser processing machine.

2019 Development of the new INTEGREX i-H Series of Multi-Tasking machines.

2019 Development of the next-generation MAZATROL SmoothAi CNC system with MAZATROL TWINS software.

2019 Development of the VARIAXIS C-600 simultaneous 5-axis machining center.

2019 The Yamazaki Mazak Museum of Machine Tools opens.

2020 Development of the FJW-100/160 5-face double-column machining center.

2020 Development of the new MAZATROL SmoothEz CNC.

2020 Development of the VARIAXIS i-800 NEO simultaneous 5-axis machining center.

2001 - 2010

Teruyuki Yamazaki is appointed Chairman and CEO.

Yoshihiko Yamazaki is appointed Senior Vice Chairman.

Tomohisa Yamazaki is appointed President.

Development in Japan of the INTEGREX e Series of advanced Multi-Tasking machines.

Mazak México relocates to Monterrey and expands the México Technology Center.

Yamazaki Mazak Japan headquarters and 4 manufacturing plants in Japan obtain ISO-14000 certification.

Development of the NEXUS series, a new generation of world-class machine tools produced globally.

Development in Japan of the UN-600V and UN-600H for high productivity in extremely compact spaces.

Development in Japan of the MAZATROL MATRIX new-generation CNC system.

Addition of intelligent functions to all INTEGREX 200-IV models.

In Florence, Kentucky, Mazak renovates and expands its parts facility, renaming it the North American Parts Center and adding a new automated storage system.

The National Technology Center in Florence, Kentucky expands from 33,000 to 69,000 square feet.

Establishment of World Technology Center in Minokamo, Japan.

The Northeast Regional Headquarters and Technology Center relocates to Windsor Locks, Connecticut.

Completion of Minokamo Plant 2 in Japan.

Installation of the first V-140N 5-axis machining center with a 6 m table in the Florence, Kentucky manufacturing plant.

Development in Japan of the INTEGREX i-150 compact Multi-Tasking machine.

Completion of the underground factory of Yamazaki Mazak Optonics Corporation in Japan.

Completion of the Cyber Spindle Factory and World Parts Center at Minokamo 2 in Japan.

Mazak Corporation receives ISO 9001:2008 certification of the Florence, Kentucky manufacturing plant.

Completion of the World Research and Development Center in Japan.

The Yamazaki Mazak Museum of Art opens in Aoi-cho, Nagoya, Japan with Teruyuki Yamazaki as director.

2001 Development of the INTEGREX e Series of advanced Multi-Tasking machines.

2002 Development of the NEXUS series, a new generation of world-class machine tools produced globally.

2006 Establishment of the World Technology Center in Minokamo, Japan.

2006Completion of Minokamo Plant 2.

2007 Development of the INTEGREX i-150 compact Multi-Tasking machine.

2008Completion of the underground factory of Yamazaki Mazak Optonics Corporation.

2010The Yamazaki Mazak Museum of Art opens.

1991 - 2000

Introduction of the first U.S.-designed VTC-41M vertical machining center at IMTS.

Development in Japan of the easily expandable PALLETECH Manufacturing System for automated production.

Mazak Corporation enters into a technical sponsorship agreement with Penske Racing South.

The Agility Forum honors Mazak for the "Best Agile Practice" in manufacturing.

In the U.S., Mazak Corporation receives the Philip B. Crosby Award for global competitiveness.

Yamazaki Mazak Japan headquarters and 4 Japan manufacturing plants obtain ISO-9001 certifications.

Establishment of the National Technology Center in Florence, Kentucky.

Development in Japan of the INTEGREX 200Y Multi-Tasking machine with Y axis.

Mazak replaces the paint equipment in the Florence, Kentucky manufacturing plant with a new powder coating system.

Completion of Oguchi Plant Cyber Factory designed for full-facility networking in Japan.

Development in Japan of the MAZATROL FUSION 640 CNC system that fuses NC and PC.

"Touch the Future 100" celebrates the 80th anniversary of the establishment of the Yamazaki Mazak Corporation.

Development in Japan of the VARIAXIS 200 multi-face 5-axis machine.

The Atlanta Technical Center relocates to Suwanee, Georgia, and becomes the Southeast Regional Headquarters and Technology Center.

Mazak replaces a six-unit V-100 FMS line in the Florence, Kentucky manufacturing plant with four new V-100N 5-axis machining centers.

Sadakichi Yamazaki, founder of Yamazaki Mazak, is inducted into the American Machinist's Hall of Innovators as a 20th-century innovator.

1993 Development of the easily expandable PALLETECH Manufacturing System for automated production.

1995 Mazak Corporation receives the Philip B. Crosby Award.

1997 Development of the INTEGREX 200Y Multi-Tasking machine with Y axis.

1971 - 1990

In Japan, Yamazaki Machinery develops the first adaptive control lathe, the MTC-1500R-AC.

Mazak begins its North American manufacturing efforts with the completion of a facility in the Greater Cincinnati, Ohio area in Florence, Kentucky.

In Japan, Yamazaki Machinery develops the YMS-30 machining system.

Completion of World Headquarters Technical Center in Oguchi, Japan.

Chicago Regional Technical Center opens.

Regional Technical Centers open in Hartford (Connecticut), Atlanta (Georgia) and Houston (Texas).

Development in Japan of the world's first conversational CNC system for lathes, the MAZATROL T-1, and the QUICK TURN 10 CNC lathe.

Yamazaki Machinery Corporation joins NMTBA (now AMT).

Flexible Manufacturing Factory (FMF) begins unattended operation at the Oguchi plant in Japan.

The Los Angeles Regional Technical Center opens.

Company name changes from Yamazaki Machinery to Mazak Corporation in North America.

Addition of an FMS System to the Kentucky manufacturing plant.

Development in Japan of the SLANT TURN 40N ATC Mill Center Multi-Tasking machine.

Completion of Minokamo plant in Japan.

Development in Japan of MAZATROL FMS unattended operation system.

Yamazaki Machinery Works, Ltd. changes its name to Yamazaki Mazak Corporation.

The Chicago Technical Center relocates to an expanded facility in Schaumburg, Illinois.

First export of Yamazaki Machinery U.K. CNC machine tools to Japan.

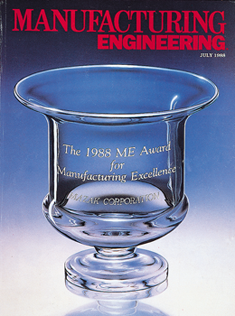

Mazak Corporation receives the All-American Top 10 Best Company Award and is named one of the 10 best manufacturing plants by Manufacturing Engineering magazine.

1974 Completion of the Yamazaki Machinery Corporation (now Mazak Corporation) Facility in Greater Cincinnati.

1976 Development of the YMS-30 machining system.

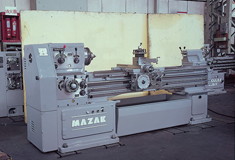

1981 Development of the world’s first conversational CNC system for lathes, the MAZATROL T-1.

1981 Development of the QUICK TURN 10 CNC lathe.

1983 Development of the SLANT TURN 40N ATC Mill Center Multi-Tasking machine.

1983 Completion of the Minokamo plant.

1988 Mazak Corporation receives the All-American Top 10 Best Company Award and is named one of the 10 best manufacturing plants.

1951 - 1970

Yamazaki Machinery begins manufacturing high-speed, high-precision lathes (lighter-duty LA and LB models and heavier-duty LC and LD models) in Japan, with a wide range of available specifications.

Expansion from Japan to overseas markets begins with the export of three LD series lathes to Indonesia.

Oguchi, Japan plant begins operation.

Yamazaki Machinery joins the Japan Machine Tool Builders' Association.

First product export – 200 LE series lathes – from Japan to U.S.A.

President Sadakichi Yamazaki passes away.

Teruyuki Yamazaki is appointed president.

Introduction of the Mazak brand.

Production of Mazak lathes begins in Japan.

Headquarters moves to new plant in Oguchi, Japan.

Establishment of Yamazaki Machinery Corporation in Long Island, New York, U.S.A.

In Japan, Yamazaki Machinery develops the MTC series, its first NC lathes.

In Japan, Yamazaki Machinery develops the first Mazak machining center, the BTC No. 5.

1963 Production of Mazak lathes begins after the introduction of the Mazak brand.

1968 Yamazaki Machinery develops the MTC Series, its first NC lathes.

1970 Development of the first Mazak machining center, BTC No. 5.

1919 - 1950

Sadakichi Yamazaki founds Yamazaki Machinery in Nagoya, Japan.

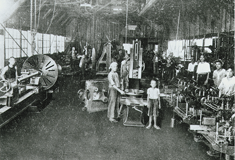

The company begins manufacturing machinery to weave straw mats.

Yamazaki Machinery establishes a new factory in Atsuta, Nagoya, Japan.

In Japan, Yamazaki Machinery begins manufacturing machine tools, including lathes and milling machines.

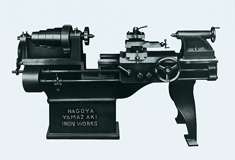

In Japan, Yamazaki Machinery develops the first commercial machine tool.

In Japan, Yamazaki Machinery develops the first motor-driven roll lathe.

Yamazaki Machinery establishes its Japan sales department.

Teruyuki Yamazaki joins Yamazaki Machinery.

1919 Sadakichi Yamazaki founds Yamazaki Machinery in Nagoya, Japan.

1928 In Japan, Yamazaki Machinery develops the first commercial machine tool.