One Source

When Tim Schneider came on board at OneSource Manufacturing Technology in 2009, he had one mission – lead the Leander, Texas, shop into the medical manufacturing sector. At the time, OneSource worked almost exclusively in the semiconductor industry, but wanted to diversify to ensure a steady, less erratic flow of incoming work.

OneSource, for the most part, had zero experience in medical part manufacturing. So, needless to say, Schneider, as the new vice president, and his team had their work cut out for them. On the plus side, the core infrastructure of the shop was solid and well established. It had already earned ISO 9001 certification, which proved a good start for eventually achieving its ISO 13485 certification, as an established medical device supplier.

Over the years, medical work at OneSource surged and quickly grew to more than 30 percent of the company's overall manufacturing operations. However, Schneider realized the shop’s existing machining capabilities limited its ability to cost-effectively produce highly complex medical components.

While the shop offered a solid base of fundamental machining technologies, such as turning and 3- and 4-axis milling, the medical parts it pursued involved a lot of complex 3D geometries and very tight tolerance requirements. Simply put, OneSource urgently needed 5-axis milling capabilities.

“As we got further into medical, we started seeing new designs from customers that really challenged how we had initially prepared for 5-axis machining,” explained Schneider. “Initially, we accomplished 5-axis machining using our 3-axis VMCs outfitted with 4th and 5th-axis trunnion units. However, we quickly found out that such an approach hindered our part processing speed and cost effectiveness.”

The communication between the trunnion units and the VMCs on which they were mounted caused lags in positioning. Plus, the additional mounted weight of the units restricted how fast the machine tables could rapid traverse. The extra inertia involved with moving the added weight also accelerated machine wear and tear as well as generated vibration that had a negative effect on part surface finishes. But what really hindered operations was the amount of time and effort it took to achieve required levels of machining accuracy, especially when the parts in question were very small in size.

“We needed speed, accuracy and rigidity,” said Schneider, “and knew we could get it from a true integrated 5-axis machine. So, we evaluated several machine tool builders – looking closely at how they designed their 5-axis machines – and the Mazak VERTICAL CENTER UNIVERSAL (VCU) 400A/5X caught our eye. In addition to the price point, what really attracted us to the machine was the amount of capability it provided along with its exceptional construction. We were also quite surprised it had such a large table size within its small, space-saving footprint.”

“We needed speed, accuracy and rigidity,” said Schneider, “and knew we could get it from a true integrated 5-axis machine. So, we evaluated several machine tool builders – looking closely at how they designed their 5-axis machines – and the Mazak VERTICAL CENTER UNIVERSAL (VCU) 400A/5X caught our eye. In addition to the price point, what really attracted us to the machine was the amount of capability it provided along with its exceptional construction. We were also quite surprised it had such a large table size within its small, space-saving footprint.”

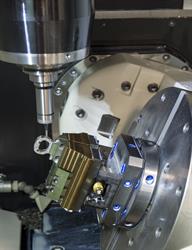

OneSource’s VCU-400A/5X vertical machining center features an integrated tilt/rotary trunnion table with roller gear cam technology. The machine has a 40-taper 12,000-rpm spindle, automatic tool changer and 30-tool storage capacity. With an X-axis stroke of 19.88", the VCU-400A/5X handles parts up to 15.740" in diameter and 12" in height.

Along with its VCU-400A/5X, OneSource has a Mazak VERTICAL CENTER SMART (VCS) 510C 3-axis vertical machining center with a 40-taper 12,000-rpm spindle, 30-tool storage capacity and 41.34" X-axis travel. The shop plans to add another 5-axis Mazak, a VCU-500A/5X that accommodates workpieces as large as 19.680" in diameter and 12" high.

According to Schneider, every job moved to the VCU-400A/ 5X has immediately reduced the cost per part by at least 15 percent through shorter cycle times. In some instances, cycle times were reduced by more than 25 percent. Our data also indicates improved set-up repeatability, which, in turn, further increases processing accuracy.

OneSource manufacturers primarily medical implants – knees, hips and a variety of spinal components – along with some associated supportive instrumentation. The shop collaborates with customers to work through any manufacturing/manufacturability issues and will run prototype/test parts during developmental stages.

OneSource manufacturers primarily medical implants – knees, hips and a variety of spinal components – along with some associated supportive instrumentation. The shop collaborates with customers to work through any manufacturing/manufacturability issues and will run prototype/test parts during developmental stages.

Parts at OneSource range in size from 0.125" square up to 18" square. Typical tolerances are +/- 0.005 and as tight as +/-0.0005", and materials include stainless steels, titanium, cobalt chrome, PEEK and others.

Significantly shorter cycle times and better machining accuracy from the VCU- 400A/5X technology proved especially beneficial for two particular medical parts at OneSource. While in the process of getting its first Mazak, the shop was in the development phase with a medical customer for a new cervical plate design. The titanium part involved a good deal of contour milling and specific surface finish requirements along with extremely tight 3D feature positioning tolerances. For instance, screw holes – each at various complex angles – had to be maintained in relation to the part’s overall curved shape. Thus, positioning accuracy of the machine was critical. The part also presented some tool clearance challenges.

“Right from the start, we struggled with the hole positioning and had issues with tool clearance when running preliminary parts on our existing bolt-on 5-axis equipment,” explained Schneider. “When we looked at the VCU, we thought there would still be clearance issues. However, Mazak conducted feasibility tests for us at its Southwest Technology Center and, basically, proved out the process even before we made up our minds to actually purchase the machine. The results are what really convinced us.”

While the cervical plate parts are still in the prototype/test stage, OneSource has since converted another of its customer’s medical parts over to the VCU- 400A/5X. Those parts are spinal cages made from titanium.

Like the cervical plates, the spinal cages involve very tight feature positioning tolerances. The parts also have some very small steps and pockets as well as other tiny details. The shop processes the parts in two operations. In the first, they machine between 80 and 90 percent of the part – basically all the critical features.

The VCU-400A/5X machines all the various sizes that make up the families of spinal cages 25 percent faster than did OneSource’s bolt-on 5-axis equipment. Cycle times for the spinal cages now average about an hour, and the shop will run lot sizes in the hundreds.

The VCU-400A/5X machines all the various sizes that make up the families of spinal cages 25 percent faster than did OneSource’s bolt-on 5-axis equipment. Cycle times for the spinal cages now average about an hour, and the shop will run lot sizes in the hundreds.

Alex Virag, programmer and machinist at OneSource Manufacturing Technology, runs the VCU-400A/5X. He mentioned that what is “truly amazing” about the 5-axis Mazak is the machine’s kinematics.

“The machine knows where it is exactly in relation to the part position. So if a part and/or setup needs to be off center, the machine knows where the part center is as well as its actual table center and will automatically adjust to the part’s center. All we do is probe the part, and the machine automatically adjusts on the fly. This means less potential for error and faster setups.”

On its VCS 510C, OneSource processes non-medical parts in stages using multiple vises on the machine’s table. Parts move from one vise/operation to the next and come off the machine complete. As with its Mazak 5-axis, OneSource also improves accuracy and shortens machining cycle times with its 3-axis VCS 510C. For non-medical industries, typical materials include stainless, Hiperco, PEEK, PPS, Inconel, and aluminum.

“On the VCS 510C, we just touch off the tool and run the program. So, no dry runs. The Mazaks are that precise,” commented Scott Wood, also a programmer and machinist at OneSource Manufacturing Technology. “In fact, we’ll use different tools on the same part surface, and each tool blends within a 0.0001". With our other machines, each tool would leave a noticeable step – not with the Mazaks. And tool life, especially with our finish cutters, has really improved because we get zero chatter and better harmonics.”

Medical manufacturing is one of three designated machining areas at One Source. The other two are semiconductor and general industry machining cells. The medical area is unique in that it has a wider variety of customers and customer product lines. And while it is production, it is more of a high-mix, low-volume environment that requires the ability to maintain quick set-up changeovers.

The medical area is a wholly owned subsidiary of One Source called Skeletal FX Manufacturing. All the machines in the area bear the caduceus medical symbol. According to Schneider, the medical symbol allows visiting customers to easily identify with the shop’s dedicated medical machining capabilities, and the designations serve the purpose for segregating medical required workflow.

“Our medical operations are just the start, the upgrade to true integrated 5-axis machining will eventually lead to more Mazak machines at OneSource,” added Schneider. “We continue to re-evaluate our existing cells and systems to determine where we can streamline operations, improve accuracy and boost output. And we will look to Mazak for the advanced technology to do so.”