North Star Technical

In Hamilton, Ontario, just south of Toronto in the province’s industrial heart, North Star Technical Inc. has earned a sterling reputation for customer service since its founding in 1986 based on the solid foundation of its family-owned business. In a city filled with CNC machining and repair shops, this job shop has differentiated itself from the crowd with specialized areas of expertise and close customer relationships, all backed by advanced machine tool technology.

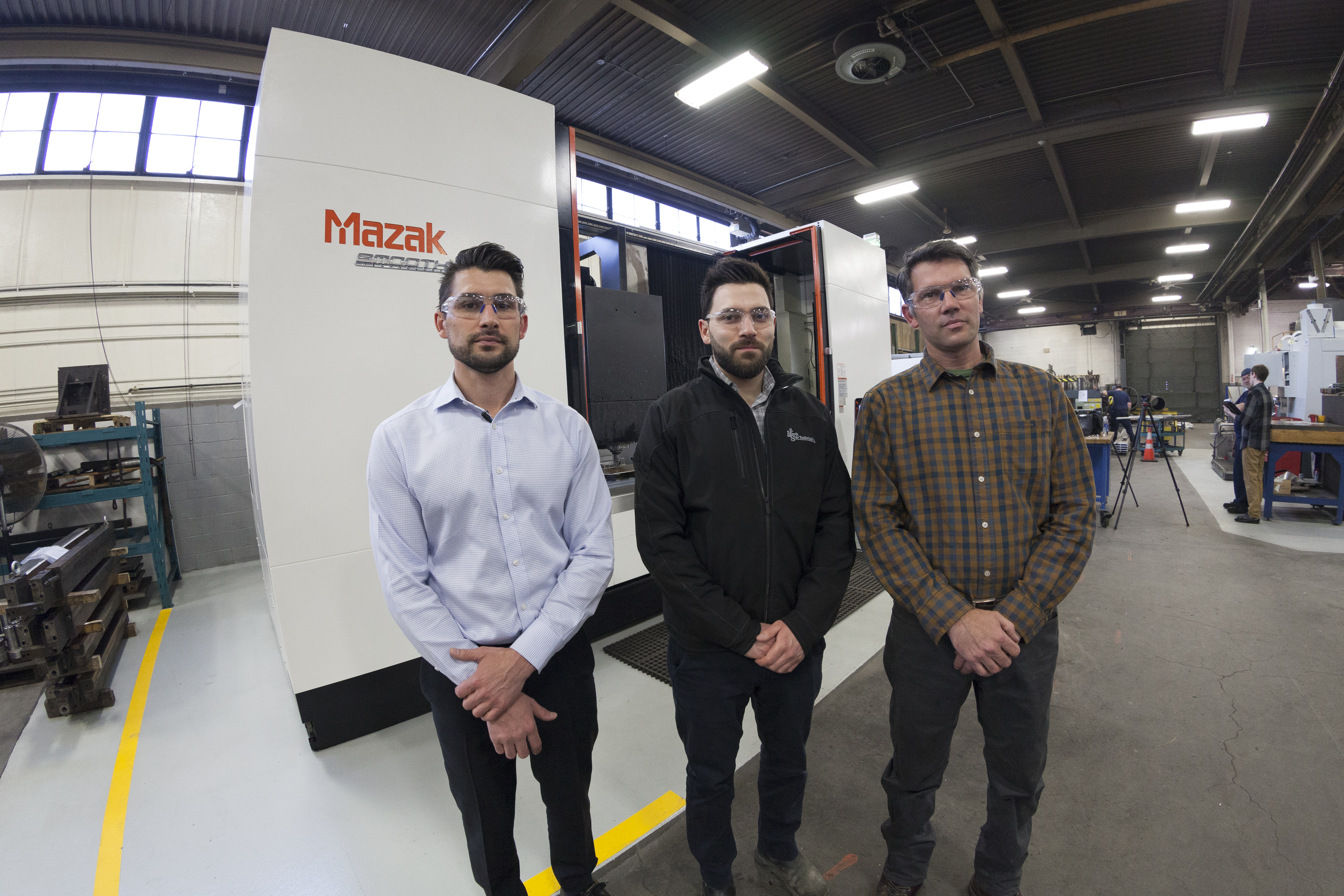

Founded by Anthony Pinelli, P. Eng., North Star has seen numerous changes across its more than 30-year history, from the widespread application of modern machining technology to the ever-growing threats of competition from shops around the world. Now overseen by Anthony’s three sons – Manager of Corporate Strategy Development James Pinelli, Director of Business Development Robert Pinelli and Plant Manager Michael Pinelli – the shop thrives through continuous improvements to its ability to provide top-level machining, welding, balancing and millwrighting services that make it a one-stop shop for repair and maintenance of heavy equipment.

The shop’s focus is on long-term customer relationships. “Our customers need more than just a part on a machine. That sets us apart from a general machine shop,” James Pinelli said. “We started in the repair industry, which was a lot of rush work, and we have converted that into more contract work. We are obviously expanding, as is our CNC machine technology, where we can service our customers more in-depth and also gain new customers with that advanced technology and the additional capacity.”

Among North Star’s customers are steel makers; oil, gas and chemical processors; food equipment manufacturers; municipalities; wastewater facilities; and transportation companies. The shop maintains, overhauls and repairs equipment on both emergency and contract bases. But North Star customers typically don’t find the shop online and order a part without any interaction – they become part of the North Star family. “Our clients have been with us for years and they come back for the relationship that we have with them. A one-time deal doesn’t work with our model,” said Robert Pinelli. “Our core business is not one part here, one part there, but actually building a relationship with the customer.”

Not only does the shop value its customer partnerships, but also those it maintains with its suppliers, and one particularly strong partnership the shop has is with its machine tool supplier, Mazak. According to Robert Pinelli, the dependable quality of Mazak machines and continued support helped prompt this most recent purchase.

But perhaps most important to the Pinelli brothers was Mazak’s customer support. “The support we got from Mazak was definitely a step above other machine tool manufacturers. We have plans to grow and add equipment over time and need to partner with a company that can support us along the way. And Mazak can.”

Presently, in addition to a wide variety of conventional mills, lathes and presses, as well as advanced balancing and welding technology, North Star has four CNC machine tools. At first, the family was skeptical: “We assumed that CNC equipment was just for high-production shops,” James Pinelli said. “But we quickly realized that is not the case and we could do quite a bit with CNCs in our job-shop style of work.” And when it decided to take the plunge, they purchased a QUICK TURN 250M CNC Turning Center in 2014 from Mazak.

The shop’s most recent Mazak machine acquisitions have been a VC-500C Vertical Machining Center, a 5-axis VC-500A/5X and a large VTC-805G Vertical Machining Center that utilizes its full travelling-column design to handle workpieces up to 32" high, 32" deep, and 118" wide. The VTC-805G is a key element of the shop’s process flexibility for larger and heavier parts: If the parts overlap the edge of the machine table, the travelling-column design facilitates machining around the stationary part’s periphery.

Made in Florence, Kentucky, the VTC-805G’s powerful 50 taper, 40 hp, 10,000 rpm spindle easily tackles a wide variety of materials, including titanium, aluminum, steel and cast iron. Its special turret-style magazine with 40-tool-position units ensures easy access to versatility for a fast-moving job shop, while the MAZATROL SmoothG CNC makes program generation for off-centerline machining, angled drilling, milling and tapping operations simple and easy.

“Now in one setup we can machine larger parts that we previously would have needed to do in a couple of setups on another machine,” said Robert Pinelli. “And we also can set up three or four parts on the machine’s long table and run them overnight.” He added that traveling-column machines evacuate chips more efficiently than table-travel machines, further facilitating untended operation and maintaining the shop’s reputation for high-quality part production.

To maximize the machine’s effectiveness, North Star specified that the VTC-805G be equipped with a part probe that reduces setup time and provides confirmation of machining accuracy. Also added were an automatic tool sensor to detect worn or broken tooling, and through-spindle high-pressure coolant to expedite deep-hole drilling.

For further process efficiency, particularly with parts featuring complex contours, North Star has also incorporated the full 5-axis capabilities of the Kentucky-built VC-500A/5X Vertical Machining Center, which is equipped with a 20" diameter table and a 15,000 rpm, 30 hp spindle. Completing the package is a full complement of options, including a probing package, coolant-through spindle and chip conveyor.

Heading up the North Star partnership on the Mazak side is Bob Kanarek, corporate account manager for Mazak Canada. “When I first met James, Robert and Michael at a trade show in Montreal, they were quite impressed with the ability to program on the Mazak control,” he recalled. “As a job shop, programming on the MAZATROL on the shop floor provides a huge benefit in terms of reduction of cycle time, setup time and programming time.” North Star made the most of this advantage with three years of unlimited programming training, provided free with the purchase of each machine at Mazak’s Canada Technology Centre in Cambridge, Ontario. Kanarek also facilitated on-site training, application support and other customer services to ensure the shop’s success.

The majority of the shop’s work, which includes parts like large gearboxes, pumps, crushes and centrifuges, is very low volume, often involving runs of only one or two parts. Robert Pinelli said, “Once in a while we will get an order of 100 pieces, but that is only once or twice a month.” Workpieces weigh as much as five tons, and materials range from aluminums, stainless and mild steels to high-strength alloys and cast iron.

The jobs that fit North Star best are those that take advantage of its full millwrighting, welding, machining and balancing capabilities, as well as the shop’s advanced machining capabilities. The shop also has particular expertise when it comes to reverse engineering worn or broken parts that OEMs no longer support. “When we have a project that incorporates all those services under our roof, we excel and are quite competitive for customers who otherwise would be sending those services out,” James Pinelli said.

For example, maintenance on a large aggregate crushing unit includes disassembly by millwrights, assessment of needs for repair or refurbishment, hard facing and weld buildup on wear areas, machining to rebuild shafts or gearboxes, and balancing of rotating components. Millwrights then reassemble the unit, and the maintenance routine is completed without the delays and expense of outsourcing the different operations – particularly when processes are able to be combined and performed in a single setup on the shop’s Mazak equipment.

The shop’s relationship-building approach also informs its relationship with its 32 employees, who work in two shifts. North Star considers its employees to be members of its extended family, and most have served the company and its customers for well over a decade. Or, as Robert Pinelli said, “Flexible Mazak machines enable one person to run two or three machines. Instead of adding more manpower we’d rather grow the number of machines in the shop and utilize the excellent staff we have.”

According to James Pinelli, “We focus on the service and quality we try to provide our customers, and Mazak definitely offers that same level of quality and service to their customers. We share those values.” And to that end, North Star continues to search out ways to improve upon its business relationships, working with like-minded companies such as Mazak to earn the trust of customers through the acquisition of manufacturing technology that unleashes the shop’s full potential.

Original article in Shop Metalworking Technology

Original Article