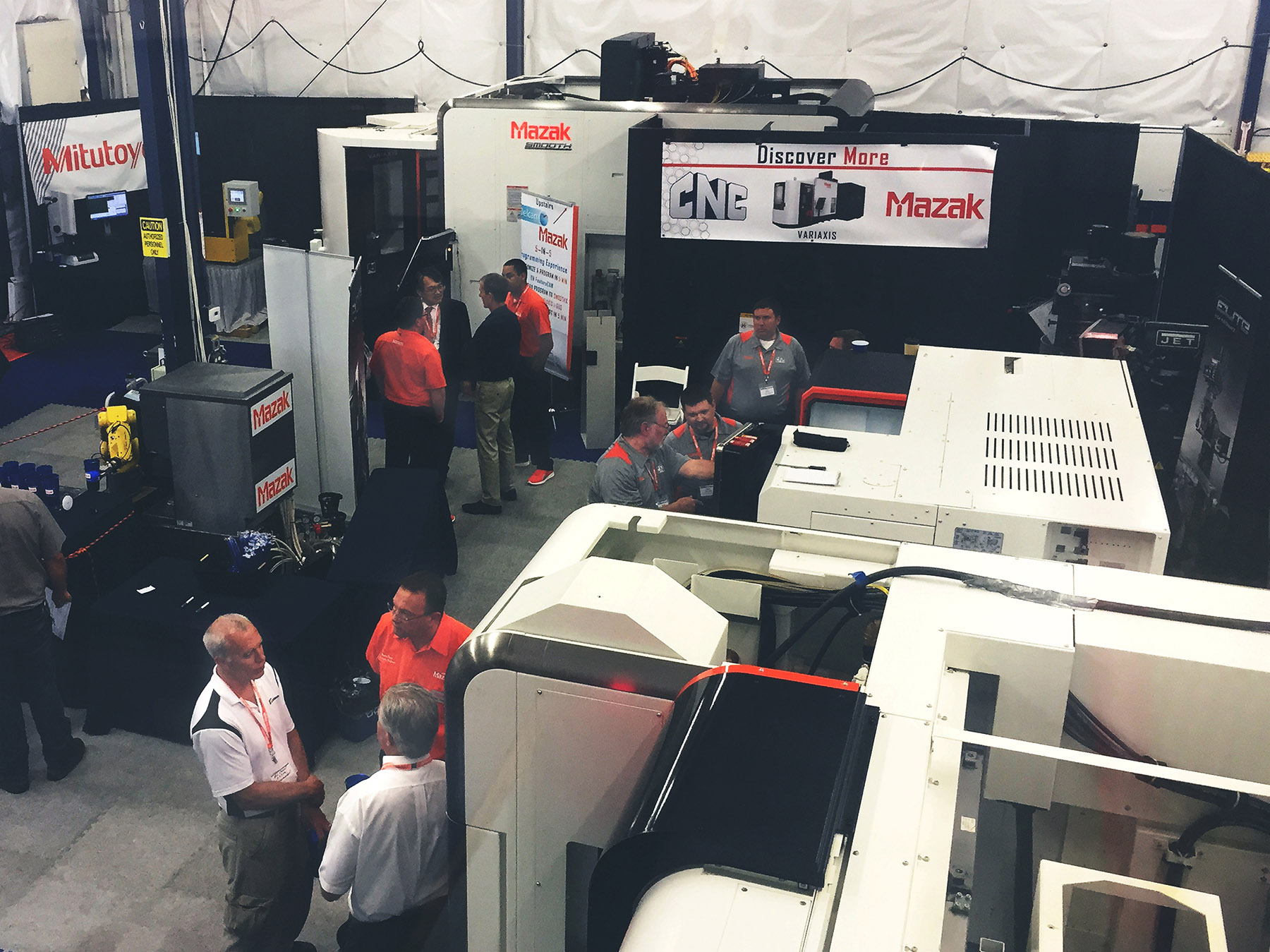

One of Mazak’s newest partners CNC Machine Services hosted its 5th Annual Summer Open House event. Held on August 12-14, the event featured some of Mazak’s most advanced manufacturing systems including its SMOOTH Technology platform, multi-tasking and 5-axis machining technology and PALLETECH automation. There was also a well-attended Student Day that welcomed individuals from the Aerospace Joint Apprenticeship Committee (AJAC) program.

On the technology side, CNC Machine Services showcased Mazak’s VERTICAL CENTER UNIVERSAL (VCU) 300A 5X Vertical Machining Center, QUICK TURN UNIVERSAL (QTU) 250MY Multi-Tasking Turning Center, INTEGREX i-150 Multi-Tasking Machine and VARIAXIS i-600 Vertical Machining Center with two-pallet changer (2PC).

On the technology side, CNC Machine Services showcased Mazak’s VERTICAL CENTER UNIVERSAL (VCU) 300A 5X Vertical Machining Center, QUICK TURN UNIVERSAL (QTU) 250MY Multi-Tasking Turning Center, INTEGREX i-150 Multi-Tasking Machine and VARIAXIS i-600 Vertical Machining Center with two-pallet changer (2PC).

Five-axis machining was a hot topic and drew much attention from local manufacturers in attendance. To demonstrate full simultaneous 5-axis capability, CNC Machine Services programmed an actual customer part, sent the program out to the shop floor and ran it on the Mazak VARIAXIS i-600. The machine also showcased the power of Mazak’s SMOOTH Technology that encompasses the brand new MAZATROL SmoothX CNC.

SMOOTH is a complete process-performance technology platform that spans the entire part-production landscape, from programming to metal removal to automation to data collection. And in addition to the SmoothX control, the technology involves new machine hardware and servo systems for total performance improvement. CNC Machine Services event attendees quickly realized SMOOTH would shorten their machining cycle times, especially in fine increment programs for simultaneous 5-axis operations and free-form die-mold machining.

The INTEGREX i-150 also showed event attendees full 5-axis machining, but combined with the power of multi-tasking. The machine provides the capabilities of both a high-powered turning center and a full-function machining center to produce parts in single setups.

Open house attendees met Mazak’s simple but innovative VCU 300A 5X and QTU 250MY machines. The full 5-axis VCU 300A 5X sports a rotary/tilt table and is well suited for high-precision small parts processing for a variety of industries. The versatile QTU 250MY has a small-footprint along with a milling turret and Y-axis off-centerline movement that give the turning machine its multi-tasking capabilities.

Open house attendees met Mazak’s simple but innovative VCU 300A 5X and QTU 250MY machines. The full 5-axis VCU 300A 5X sports a rotary/tilt table and is well suited for high-precision small parts processing for a variety of industries. The versatile QTU 250MY has a small-footprint along with a milling turret and Y-axis off-centerline movement that give the turning machine its multi-tasking capabilities.

During the CNC Machine Services Student Day, AJAC students came from all over the region. AJAC is a statewide, nonprofit 501(c)(3) aerospace and advanced manufacturing registered apprenticeship program. Its goal is to provide skills learning to adult men and women and help veterans transition into the workforce via careers in manufacturing.

Area employers and employees comprise AJAC’s advisory committee that develops and implements the individual registered apprenticeship programs according to industry needs. Currently, those programs include machinist (aircraft oriented), aircraft mechanic, precision fabricator, tool & die and industrial maintenance mechanic.

CNC Machine Services gladly welcomes AJAC students to all its open house events. Mark Harris, president, and Deana Harris, vice president at CNC Machine Services both believe it is very important to be involved with the program – doing so is not only good for the community but for the manufacturing industry as well.

Over 200 Open House attendees helped CNC Machine Services celebrate its new partnership with Mazak. For Mark and Deanna, the event exceeded their expectations. Customers, according to Mark, were extremely impressed with the Mazak technology, and he added that the move to Mazak is already proving a benefit to CNC Machine Services and, most importantly, to its customers.