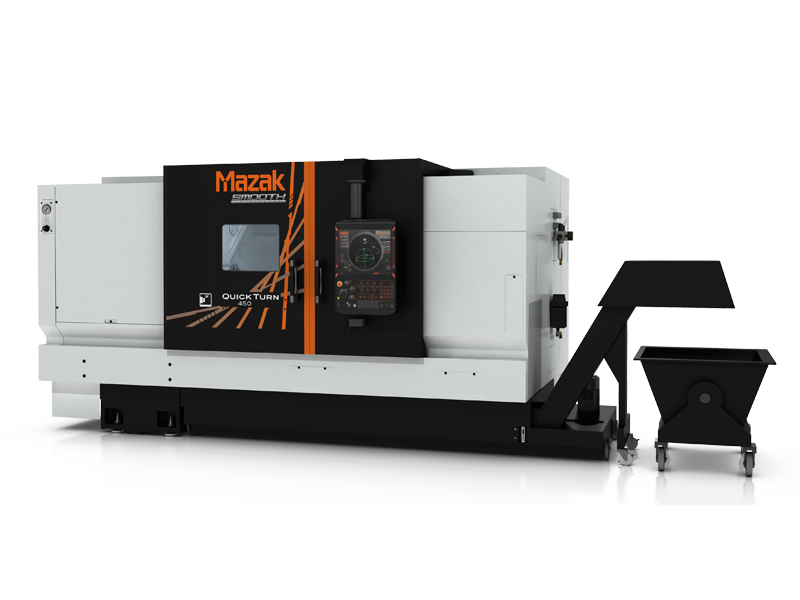

QUICK TURN 450

MACHINE DESCRIPTION:

The Kentucky-made QUICK TURN 450 CNC Turning Center brings together advanced technology, productivity and value to deliver exceptional performance for shops of all sizes.

The machine features a standard, large spindle bore capacity of 7.28" for a variety of through-hole applications. The standard 50-hp integral turning spindle motor allows the QUICK TURN 450 to process a wide range of medium or larger-diameter parts.

The QUICK TURN 450 features a machine design that minimizes vibration during heavy duty turning to create exceptional surface finishes and maintain long tool life. With no transmission belts, pulleys or gears, its integral spindle/motor delivers more of its high-efficiency power to the tool tip for cutting purposes.

MACHINE CHARACTERISTICS:

- Powerful main turning spindle

- CNC programmable tailstock

- Through-hole chuck packages

- Automatic tool eye

Machine Specifications

| Specification | Bed Length - 40 in / 1000 mm | Bed Length - 80 in / 2000 mm | |

|---|---|---|---|

| Capacity | Maximum Swing | 33.26 in / 845 mm | 33.26 in / 845 mm |

| Maximum Machining Diameter | 22.830 in / 580 mm | 22.830 in / 580 mm | |

| Maximum Bar Work Capacity | 7.3 in / 185 mm | 7.3 in / 185 mm | |

| Maximum Machining Length | 38.540 in / 979 mm | 79.880 in / 2029 mm | |

| Main Spindle | Chuck Size | 18 in | 18 in |

| Maximum Speed | 2000 rpm | 2000 rpm | |

| Motor Output (30 minute rating) | 50.0 hp / 37 kw | 50.0 hp / 37 kw | |

| Turret (Upper) | Number of Tools | 12 | 12 |

| Feed Axes | Travel (X Axis) | 12.20 in / 310 mm | 12.20 in / 310 mm |

| Travel (Z Axis) | 42.12 in / 1070 mm | 83.46 in / 2120 mm | |