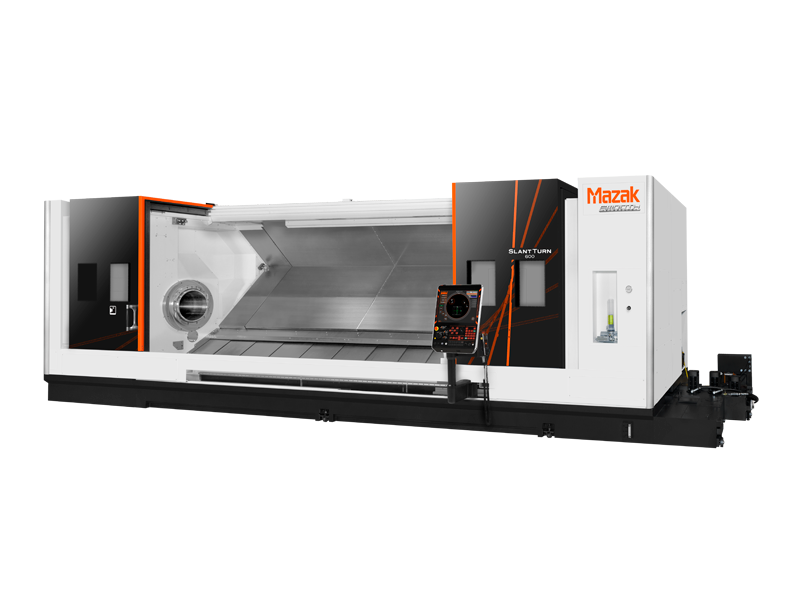

SLANT TURN 600

MACHINE DESCRIPTION:

The SLANT TURN 600 is a powerful, heavy-duty,high torque, big-bore turning center for large part turning applications, such as oil field pipe /casings, pipeline control valves, turbine components and aircraft engine parts.

The ST-600 offers maximum machining lengths up to 160", and depending on chuck size, maximum machining diameters to 36", for long, large-diameter parts. The standard spindle bore is 14.7" diameter and can handle large diameter pipe and other components that required front and rear chucking.

MACHINE CHARACTERISTICS:

- High torque, high Horsepower geared headstocks for heavy-duty cutting

- Various front and rear chuck options available

- 14.7" diameter Spindle Bore

- 12-position non-lift drum turrets for rapid tool indexing

- NC servo-driven tailstocks

- Mazak MX Hybrid Roller Guide System

Caractéristiques de la machine

| Spécification | Bed Longueur - 2000U mm | Bed Longueur - 3000U mm | Bed Longueur - 4000U mm | |

|---|---|---|---|---|

| Capacité | Balançoire maximum | 40.94 in / 1040 mm | 40.94 in / 1040 mm | 40.94 in / 1040 mm |

| Diamètre d'usinage maximum | 35.830 in / 910 mm | 35.830 in / 910 mm | 35.830 in / 910 mm | |

| Usinage Longueur maximale | 79.090 in / 2009 mm | 123.780 in / 3144 mm | 158.780 in / 4033 mm | |

| Broche principale | Chuck Taille | 21 in | 21 in | 21 in |

| Vitesse de pointe | 500 rpm | 500 rpm | 500 rpm | |

| Tourelle (Haute) | Nombre d'outils | 12 | 12 | 12 |

| Nourrir axes | Voyage (axe X) | 18.31 in / 465 mm | 18.31 in / 465 mm | 18.31 in / 465 mm |

| Voyage (axe Z) | 85.24 in / 2165 mm | 129.92 in / 3300 mm | 164.96 in / 4190 mm | |