MACHINES & TECHNOLOGY

Our goal for every DISCOVER event is to exceed all expectations. And it’s our belief that DISCOVER 2015 will once again set a new standard for private manufacturing events. In fact, you’ll experience levels of machine tool technology that’s among the highest in the industry.

MACHINES IN ACTION

Watch our latest machine tools perform advanced Multi-Tasking, 5-axis, milling and turning operations to productively process real-world parts with complete accuracy. These machines will feature the latest ancillary machine tool equipment from several of our Value Inspired Partners. Applications experts will also be on standby during the demonstrations to discuss total manufacturing solutions as well as part-processing improvements.

HYBRID MULTI-TASKING

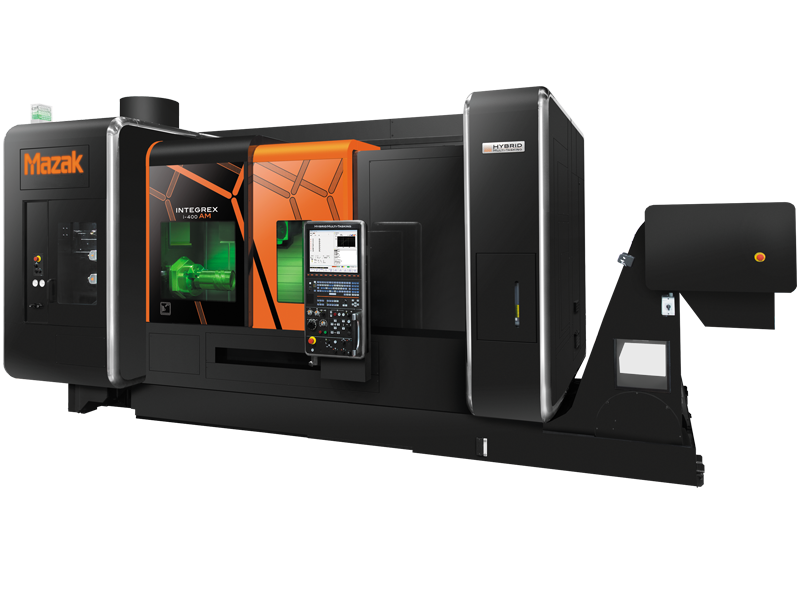

INTEGREX i-400AM

An innovative alternative to conventional part design and processing, this HYBRID Multi-Tasking machine integrates laser cladding with our most advanced full-5-axis milling and turning capabilities. Perfect for small-lot production of difficult-to-cut materials, the machine easily generates/clads near-net-shape component features then completes them via high-precision finish machining operations. It’s also well suited for repairing damaged high-value parts.

MULTI-TASKING

HQR 250MSY + MAZATROL SmoothG CNC

Perfect for high-volume operations, this Multi-Tasking turning center features a highly productive twin-spindle, twin-turret configuration with Y-axis capabilities for DONE IN ONE® part processing and unmatched throughput. Pair it with an optional bar feeder or robot loader/unloader for continuous unmanned operations. At DISCOVER 2015, the machine will perform hob cutting in steel workpiece material.

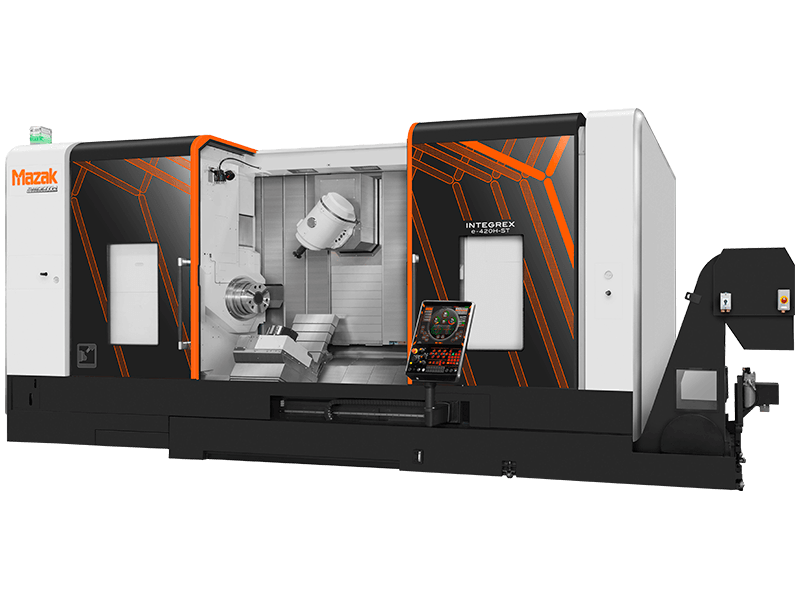

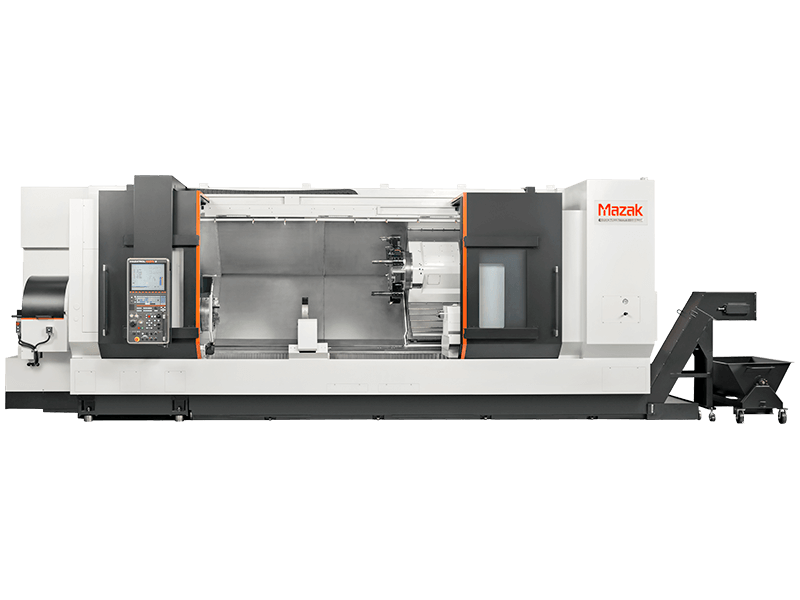

INTEGREX e-420H-ST + MAZATROL SmoothX CNC

This machine productively processes heavy, shaft-type workpieces with large diameters in single setups. It has a lower turret with a 16.5" Y-axis that works alongside twin turning spindles and a main milling spindle for the ultimate 5-axis DONE IN ONE part processing. Tool storage capacities of 40, 80 or 120 tools ensure continuous operations.

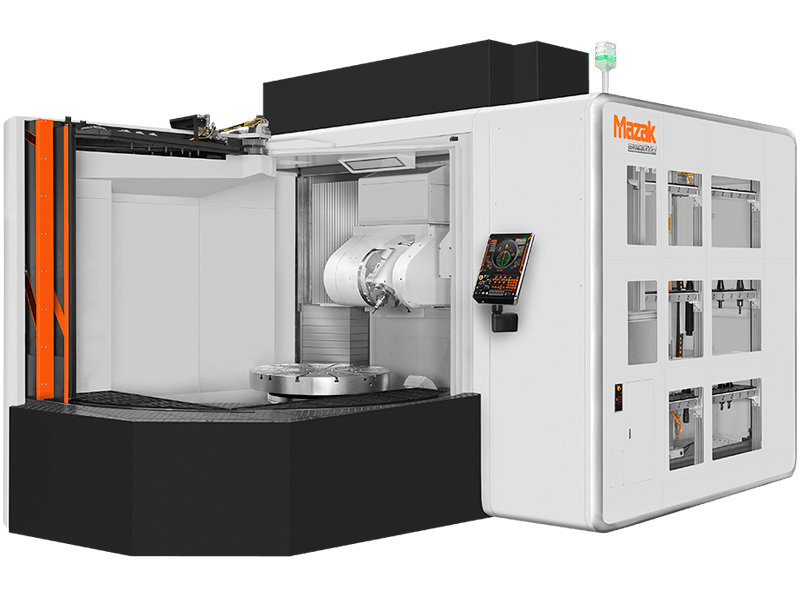

INTEGREX e-1600V/10S + MAZATROL SmoothX CNC

Easily the most advanced machine tool for processing large, complex parts in single setups. It blends 5-axis machining with turning operations to ratchet up production versatility and output when cutting aluminum, steel and high-temperature alloy workpiece materials. This Multi-Tasking functionality together with a maximum workpiece capacity of 90.5" in diameter and 63" high make it perfect for the energy and jet engine industry sectors. At DISCOVER 2015, the machine will feature the new MAZATROL SmoothX CNC and demonstrate its ability to effectively process an engine casing.

INTEGREX i-100 BARTAC-S + MAZATROL SmoothX CNC

Perfect for small, complex part production, this machine uses a large 4.4" spindle bore to bring high levels of productivity to the machining of bar material up to 4" in diameter. It also features two turning spindles and a milling spindle for full 5-axis machining and DONE IN ONE operations. An Intelligent Bar Loader System automatically feeds out material the required distance from the chuck and minimizes the bar remnant.

INTEGREX i-100ST + MAZATROL SmoothX CNC

Able to machine complex parts up to 19.67" in diameter and 33.62" long, this versatile machine has two turning spindles, a milling spindle and lower turret to carry out first and second machining operations simultaneously or perform required sequential operations on a single workpiece.

INTEGREX i-200ST + MAZATROL SmoothX CNC

This advanced machine brings maximum versatility and throughput to the production of complex parts up to 25.91" in diameter and 59.8" long. It combines the capabilities of a high-powered turning center and full-function machining center as well as includes a second turning spindle and lower turret to produce parts in single setups.

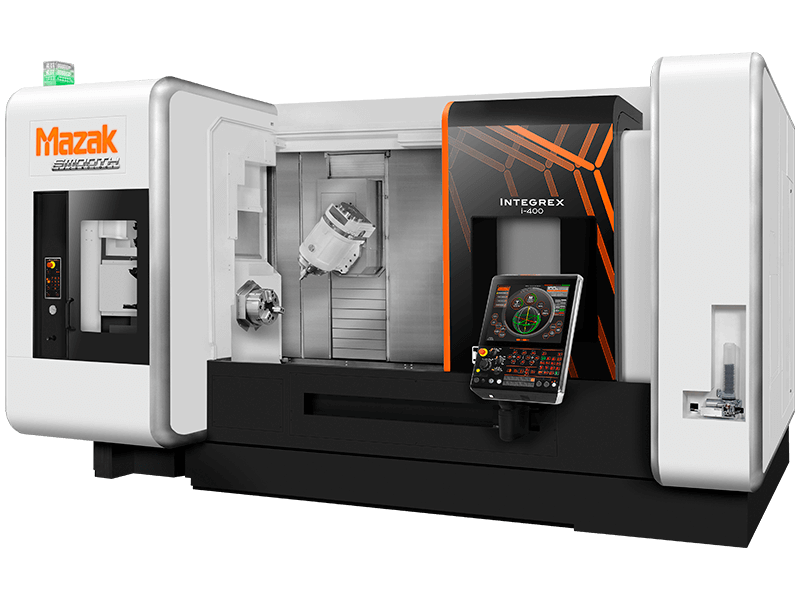

INTEGREX i-400S + MAZATROL SmoothX CNC

Perfect for shops processing medium and large workpieces, this versatile machine combines the capabilities of a high-powered turning center and full-function machining center to produce complex parts in single setups. It features a second turning spindle for DONE IN ONE operations and works to minimize fixtures, tools, handling and non-cut time.

INTEGREX i-630V/6 + MAZATROL SmoothX CNC

The INTEGREX i-630V/6 Multi-Tasking machine combines full 5-axis milling, powerful turning operations and pallet-changing capabilities to productively process large, highly complex parts such as jet engine components and spiral bevel ring gears. Because the machine is able to perform milling, turning, boring and drilling operations in single setups, manufacturers can reduce the inaccuracies that occur when moving heavy parts across multiple workstations as well as eliminate work-in-process inventory.

INTEGREX j-200S + MAZATROL SmoothG CNC

This machine brings maximum value, precision and throughput to the production of complex medium-sized workpieces. It's able to process parts complete in single setups via two turning spindles with C-axis control and a milling spindle that performs 4-axis simultaneous machining and 5-axis tool tip positioning. At DISCOVER 2015, the machine will demonstrate its high-performance turning and angular milling capabilities when cutting a feed screw from steel.

MEGA TURN 500M Automation Cell

This high-speed, high-accuracy vertical turning center brings unsurpassed performance to large part production. It provides powerful cutting capability for loads up to 1,100 pounds via a high-torque 30-hp, 3,000-rpm integrated main drive motor/spindle and high-rigidity 12-position drum turret. The machine’s high-output, 10-hp rotary tool spindle and precise C-axis indexing make handling a wide range of machining requirements possible. An optional automatic tool changer system eliminates boring bar interference and increases tool storage capacity. At DISCOVER 2015, the machine will perform brake rotor cutting demonstrations.

QUICK TURN NEXUS 250 MSY

This Multi-Tasking turning center brings advanced technology, productivity and value to shops processing workpieces up to 14.75" in diameter and 21.275" long. It has a high level of production versatility thanks to two turning spindles, a milling turret with a rotary tool spindle and Y-axis capability. For fully automated operations, the machine can be outfitted with a bar feeder or gantry robot. At DISCOVER 2015, the machine will perform gear cutting operations in steel, including OD hobbing and ID broaching.

QUICK TURN NEXUS 550 MY

Ideal for the heavy vehicle and energy industries, this Multi-Tasking turning center, with spindle through-bore sizes ranging from 10.8" to 14.7", brings unmatched productivity and reduced cycle times to long, large-diameter shaft-type part production. It features a tool turret with Y-axis movement for performing milling, drilling and threading operations.

QUICK TURN UNIVERSAL 250 MSY

Perfect for job shops seeking an affordable, highly versatile machine, this turning center with Multi-Tasking capabilities employs a milling turret, second turning spindle and Y-axis functionality to process small parts in single setups, resulting in improved accuracy and significant time savings.

QUICK TURN UNIVERSAL 350 MY

Never choose between Mazak quality and affordability when it comes to precision small parts production. This highly versatile turning center with Multi-Tasking capabilities features a milling turret and Y-axis functionality to bring maximum efficiency, reliability and value to job shops across all industry segments.

QUICK TURN ZENITH 250

Perfect for job shops, this new Kentucky-built turning center features a revolutionary new digital Y-axis along with a unique turret configuration. Unlike a conventional tool turret, this one is parallel to the main turning spindle and can turn counterclockwise and feed in the Z-axis to perform Y-axis machining. Also, the configuration eliminates the need for an actual Y-axis slide mechanism, increasing its cost competitiveness without sacrificing performance. At DISCOVER 2015, the machine will demonstrate its high-performance value in medical part production.

VARIAXIS i-800T + MAZATROL SmoothX CNC

Perfect for processing thin workpieces from a variety of materials in single setups, this all-new vertical machining center effectively combines 5-axis simultaneous milling with advanced turning capabilities. It is one of the few machines with a trunnion-style tilting table to feature a 50-taper spindle and Multi-Tasking operations. The MAZATROL SmoothX CNC also allows the machine to effectively perform at high speeds, even when skiving and grooving. As the largest machine in the VARIAXIS series, the i-1050T can accommodate workpieces up to 49" in diameter and 35" high.

VARIAXIS i-1050T + MAZATROL SmoothX CNC

Designed with high levels of productivity and precision in mind, this machine combines multiple-surface, simultaneous 5-axis milling with advanced turning operations for DONE IN ONE® parts production. It is among the few machines with a trunnion-style tilting table to feature a 50-taper spindle and Multi-Tasking operations. At DISCOVER 2015, the machine will employ a 10,000-rpm spindle to demonstrate its exceptional accuracy and throughput when cutting steel workpiece materials.

5-AXIS

VERTICAL CENTER UNIVERSAL 300A 5X

This simple but innovative vertical machining center with a 5-axis rotary/tilt trunnion table brings advanced technology and production value to high-precision small parts processing for a variety of industries. Plus, it’s available with a variety of maximum spindle speeds to exceed all metal removal requirements.

VERTICAL TRAVELING COLUMN 800/30SDR

This vertical machining center features a high-speed, 40-taper spindle, full traveling column design and fixed table for processing extremely long, heavy workpieces. And with an optional table partition, the table easily becomes two separate work areas. When paired with a rotary table, it can achieve simultaneous 5-axis machining and increased productivity.

VORTEX i-800V/8 + MAZATROL SmoothX CNC

This vertical machining center with a 31.5" square pallet is perfect for job shops and aerospace part manufacturers focused on value, precision and high-volume production. Its tilting spindle allows for the full 5-axis machining of complex contours on large parts, while a two-pallet changer offers unattended operations and off-cycle part setups.

VCU 500A 5X + MAZATROL SmoothX CNC

Perfect for processing small, complex workpieces, this simple but innovative vertical machining center with a 5-axis rotary/tilt trunnion table brings advanced technology and production value to a variety of industry segments. Plus, it's available with a variety of maximum spindle speeds to exceed all metal removal requirements.

MILLING

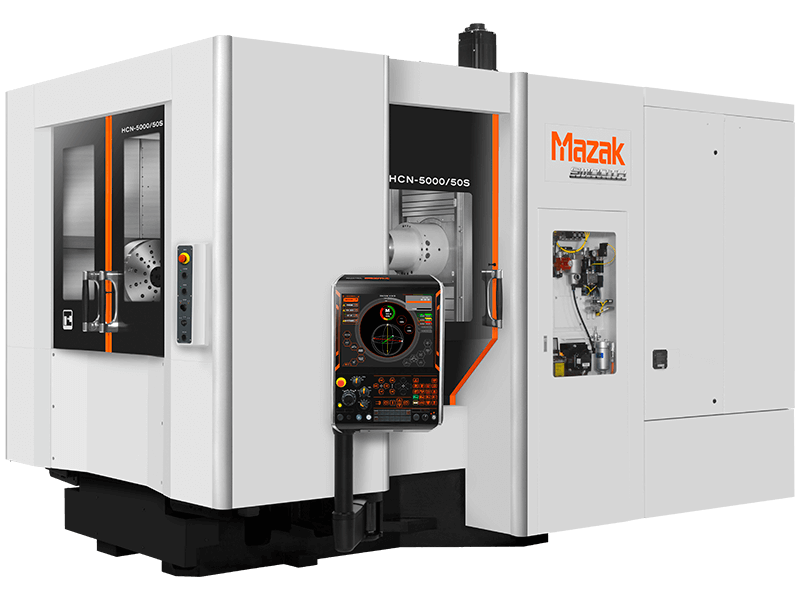

HCN-5000/50 PALLETECH + MAZATROL Smooth PMC

This machine brings precision, reliability and value to the high-volume production of large, heavy parts. It features a spacious work envelope and pallet size as well as a fast rapid traverse speed and rigid, reliable spindle. Pair it with a PALLETECH pre-engineered palletized manufacturing system for dramatically improved machine utilization. At DISCOVER 2015, the machine will feature a 10,000-rpm, CAT 50 spindle and demonstrate its ability to productively process a suspension bracket from steel.

HCN-6800 + MAZATROL SmoothG CNC

This machine combines advanced technology and outstanding value for achieving maximum performance when cutting virtually any type of material. It features spacious work envelope and pallet size as well as a fast rapid traverse speed and rigid, reliable spindle options in standard, high speed and high torque. A Hard Metal (HM) package is available for this machine so it can easily tackle the heavy duty machining of tough materials such as titanium and Inconel. At DISCOVER 2015, the machine will feature a 10,000-rpm, CAT 50 spindle and demonstrate its ability to effectively perform spiral grooving operations.

HORIZONTAL CENTER UNIVERSAL 4000

Perfect for job shops, this high-value, highly productive horizontal machining center features a 15.75" square pallet and can produce precision parts up to 25” in diameter and 35” high. Made in Kentucky, it meets a variety of different production requirements though its various options, including 12,000 and 20,000-rpm spindle speeds; 40, 80 and 120-tool magazines; and either an NC-positioning table for precise 4-axis machining or NC-rotary table for accurate simultaneous 4-axis contouring.

HORIZONTAL CENTER UNIVERSAL 5000 + Robot Cell

Designed with high-volume, low-mix shops in mind, such as automotive part makers, this Kentucky-made horizontal machining center with an excellent price-performance ratio features a 19.69" square pallet and meets a variety of different production requirements though its various options, including 12,000 and 20,000-rpm spindle speeds; 40, 80 and 120-tool magazines; and either an NC-positioning table for precise 4-axis machining or NC-rotary table for accurate simultaneous 4-axis contouring.

VERTICAL CENTER NEXUS 530C

This vertical machining center brings advanced technology, value and productivity to a range of machining applications, including our own Kentucky manufacturing operations. It has a single table design that can process large parts or multiple smaller workpieces in a single machine setup. Available in rpm speeds of 15,000 or 12,000, the machine’s spindle allows for an effective balance of speed and torque. Pair the machine with an optional two-pallet changer to achieve even higher productivity.

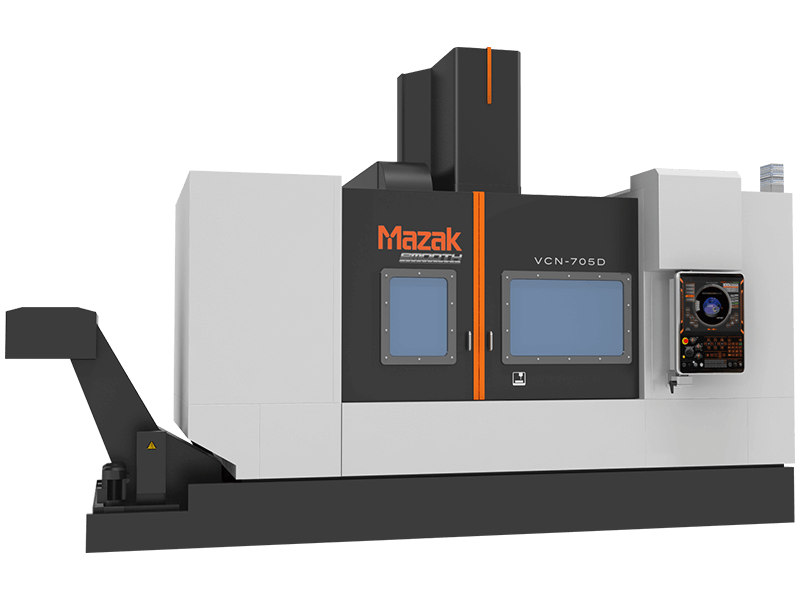

VCN-705D + MAZATROL SmoothG CNC

This new high production vertical machining center features a 60-tool ATC magazine with a specially designed carousel. The horizontally configured L-shaped carousel puts tool pockets well within reach for easy and fast loading of big 50-taper tooling and eliminates having to use step stools. At DISCOVER 2015, the machine will demonstrate its advanced 3D milling capabilities in mold work.

VCU 500C

This simple but innovative vertical machining center with a 3-axis table brings advanced technology and production value to accurate small parts processing for a variety of industries. It’s available with a variety of maximum spindle speeds to exceed all metal removal requirements.

VTC 805G + MAZATROL SmoothG CNC

This completely new vertical traveling column machine boasts the industry’s longest Y-axis stroke of 32” as well as an X-axis measuring 120”. It has a powerful 50-taper spindle and accommodates up to 40 tools in its ATC magazine. A center partition allows the machine’s table to become two separate work areas – one for loading parts and the other for use inside the machine.

TURNING

QUICK TURN UNIVERSAL 200

This small-footprint, 2-axis turning center brings efficiency, reliability and value to those processing precision small parts from aluminum, cast iron, steel and much more. It features an integral spindle/motor headstock and innovative turret design with multiple tool configurations that are above and beyond what you’d find on competitive products.

QUICK TURN PRIMOS 100 S + Robot Cell

Making its North American debut at DISCOVER 2015, this compact turning center offers high-accuracy, high-speed machining via a rigid integral spindle/motor design that does not utilize vibration-causing gears or belts. The machine’s 5,000-rpm spindle delivers high-torque capability in the low-speed range to further enhance its performance rigidity. It also has a non-lift, servo-driven 8-position turret that indexes at high speeds to reduce non-cut times. The machine easily pairs with an optional gantry loader for shops requiring unmanned operations.

SMOOTH TECHNOLOGY

Make way for higher levels of productivity with our SMOOTH TECHNOLOGY platform that has revolutionized the way our machine tools perform, especially when it comes to 5-axis and contouring operations.

Spanning the entire part-production landscape, from programming to metal removal to automation to data collection, SMOOTH TECHNOLOGY seamlessly brings unmatched speed, accuracy, functionality and ergonomics to virtually every type of metalworking application.

Advanced machine design, leading-edge CNC technology and unequaled engineering resources are the foundation of SMOOTH TECHNOLOGY. And it’s the full integration of these three elements that will put you at the forefront of manufacturing innovation, allowing you to attain unbeatable cycle time speeds, unsurpassed ease of operation and undisputed productivity.

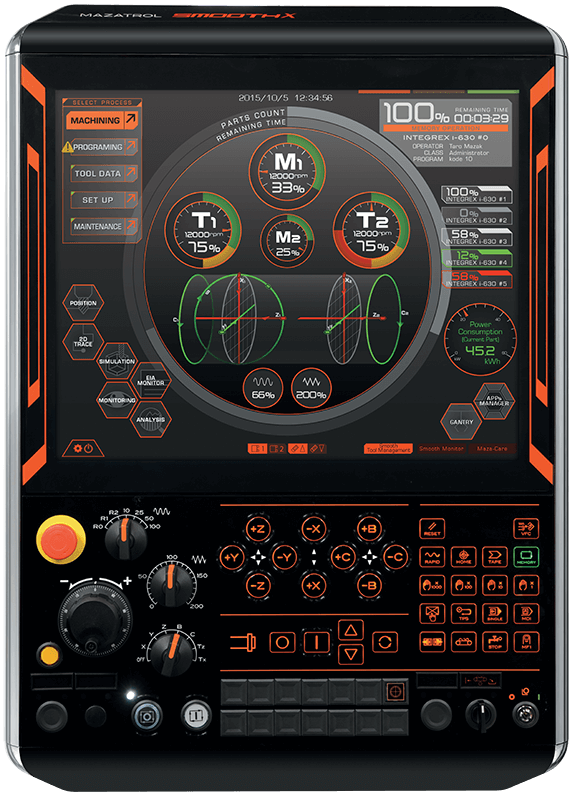

Key to the SMOOTH TECHNOLOGY platform are the MAZATROL SmoothX and SmoothG CNCs that have revolutionized the way our machine tools perform. Setting an all-new industry standard in advanced, versatile and user-friendly CNC design, SmoothX and SmoothG easily put infinite part production possibilities under your control.

MAZATROL SmoothX CNC – Highly Advanced Programming

We developed the MAZATROL SmoothX to be the fastest, most progressive CNC in the industry. Every feature and function of this control comes as a direct response to real-world issues and customer input. As a result, you benefit from shorter machining cycle times, especially in fine increment programs for simultaneous 5-axis operations and free-form die-mold machining. Plus, this CNC makes it easy for you to monitor up to five of our machines from one location.

Find the MAZATROL SmoothX CNC on these machines at DISCOVER 2015:

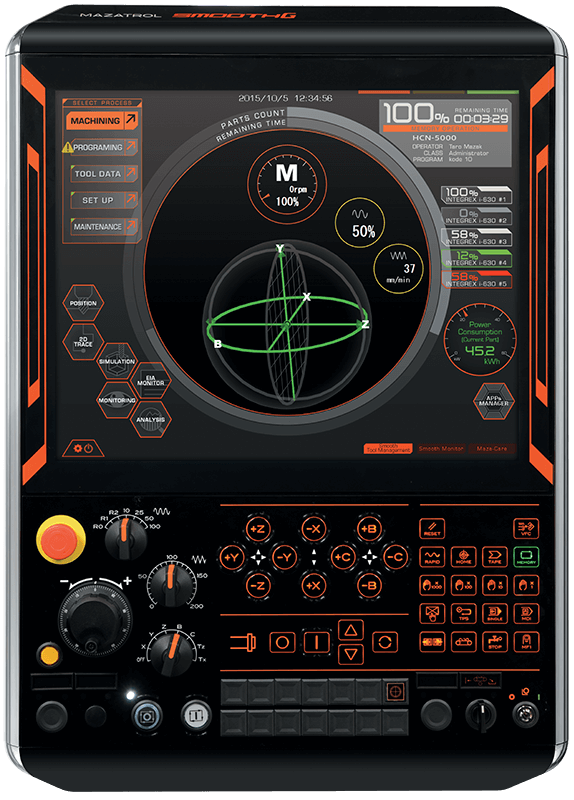

MAZATROL SmoothG CNC – Optimized Programming

The MAZATROL SmoothG CNC simplifies Multi-Tasking operations when processing parts through off-centerline machining as well as angled drilling, milling and tapping. The control incorporates a wide variety of advanced performance, programming, monitoring and maintenance-related functions that allow it to offer complete ease of use as well as ensure high-speed, high-accuracy machining performance.

Find the MAZATROL SmoothG CNC on these machines at DISCOVER 2015:

AUTOMATION

We understand the significant competitive advantages that come with having the right type of automation in your manufacturing facility. That’s why we offer the most advanced automation solutions and support resources of any machine tool builder in the industry.

At DISCOVER 2015, you’ll see how through our experience and industry partnerships, we can envision, design and implement an automation system that will boost your shop’s productivity and overall bottom line.

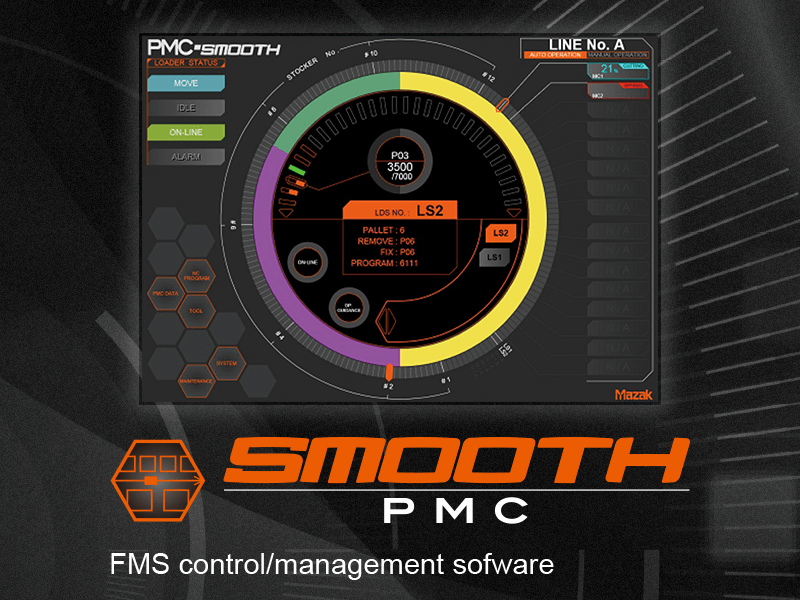

Smooth PMC

Among the most innovative examples of automation at DISCOVER 2015 will be how we’ve applied SMOOTH TECHNOLOGY to our PALLETECH System, the industry’s most advanced pre-engineered palletized manufacturing solution.

In developing SMOOTH TECHNOLOGY, we wanted to make sure this exclusive piece of automation was key to the platform. Therefore, we applied the technology to the PALLETECH Manufacturing Cell (PMC) software and are calling it Smooth PMC.

Smooth PMC features a home screen that has the same look and feel as the one on the MAZATROL SmoothX CNC. This schedule operation software predicts the necessary tools and output according to the production schedule. A variety of graphs within the software also allows for utilization analysis. Furthermore, you can use a smartphone or tablet to check the operation status of the equipment.

See it for yourself on the HCN-5000/50 that will be paired with a PALLETECH System.

DIGITAL SOLUTIONS

Factories of the future must incorporate more digital manufacturing solutions, including data analytics, intelligent machines and system monitoring, to be able to effectively compete on a global scale.

At DISCOVER 2015, we’ll demonstrate some of the advanced digital solutions we are currently involved with, including the MTConnect open communications protocol.

The data-driven manufacturing intelligence we gather from MTConnect continues to advance our manufacturing operations along with the machine tool technology we offer our customers. The protocol is a key enabler of our new Mazak iSMART Factory™ concept as well as our SMOOTH TECHNOLOGY platform that encompasses the new MAZATROL SmoothX CNC and new version 1.3 MTConnect-specification adapters.

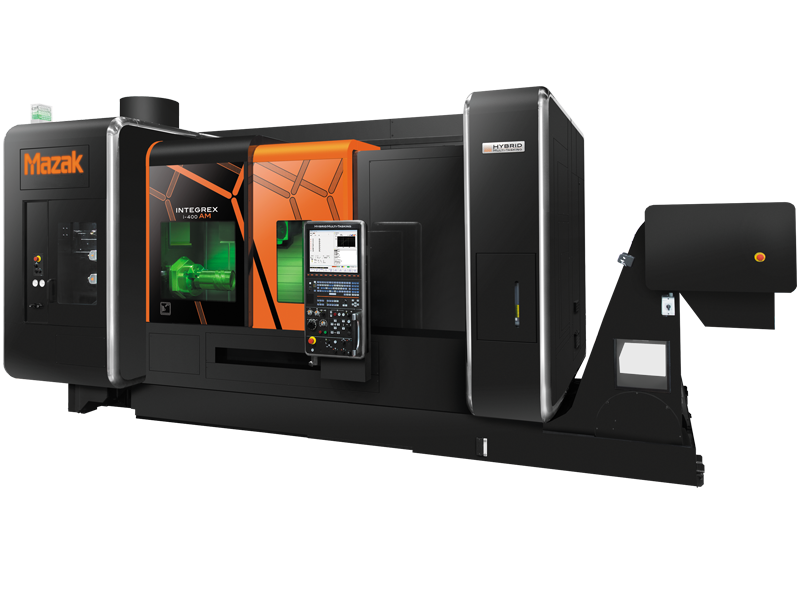

HYBRID MULTI-TASKING

Over the past decade, additive manufacturing technologies for the metalworking segment have taken a giant leap forward, with their ability to produce complex and more individualized components faster than ever.

Last year, we introduced an additive-capable model to our comprehensive machine tool portfolio: the INTEGREX i-400AM HYBRID Multi-Tasking machine. As a new, innovative alternative to conventional part design and processing, this machine uniquely integrates laser cladding with our most advanced full 5-axis milling and turning capabilities.

Perfect for small-lot production of difficult-to-cut materials, such as those used in the aerospace and medical part industries, the INTEGREX i-400AM easily generates/clads near-net-shape component features then quickly completes them with high-precision finish machining operations. It is also well suited for repairing damaged high-value parts.

At DISCOVER 2015, you’ll see two INTEGREX i-400AM HYBRID Multi-Tasking machines on display – one prototype machine and our first production system. And with additive manufacturing being a hot industry topic these days, Pete Zelinski, senior editor at Modern Machine Shop, will present on its advantages and challenges during the event.