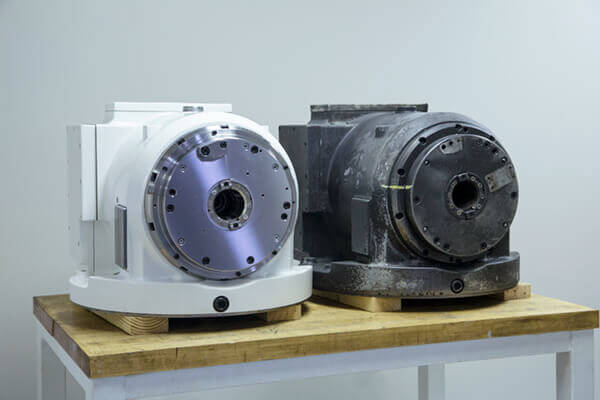

Mazak Spindle & Unit Rebuild Program

So much of production revolves around your machine’s spindle performance. When spindles are up and running, you are making parts and money. Mazak’s spindle unit rebuild and repair program ensures that you make the most of every minute in your production cycle.

Mazak fulfills your spindle needs with our comprehensive and reliable spindle rebuild and replacement spindle services program, including 30 years of spindle build expertise and the industry’s best spindle warranty. With Mazak, you get the peace of mind that comes only from working with the OEM and the benefit of the industry’s best service and support.

Mazak Spindle Services by the Numbers:

- Stock to support more than 600 different spindle variations

- 95% of new and refurbished spindle requests ship same day

- Repairs/rebuilds occur within 3-5 days

- Every spindle includes 12 hours of test stand runoff and vibration analysis benchmarking

- 1-year or 4,000-hour warranty on rebuilt spindles with Mazak certified installation

- $90 million in parts and unit inventory ($65 million in parts inventory, and $25 million in unit inventory (including ATC shifters, tables, and spindles) totaling 60,000 different part numbers in stock in Mazak's North American Headquarters in Florence, Kentucky

- $390 million in dedicated after-market inventory available globally

- Spindle repairs processed in a clean room environment and overseen by quality control teams with ISO 9001:2008 certification

Spindle Service Options

Spindle Service Options

We also offer the highest quality new and remanufactured index tables, ATC shifters, gearboxes, live tooling and milling turrets.

The Mazak Spindle Repair/Rebuild Process

The Industry's Best Spindle Repair/Rebuild Process

Mazak’s comprehensive spindle repair/rebuild process ensures that your spindle is up and running, reliably, through every cycle.

1.Comprehensive Initial Spindle Inspection and Failure Analysis

We conduct a thorough analysis to determine the root cause of spindle failure. Next, Mazak examines all spindle components for signs of wear, as well as improper fit and size. We only replace components when absolutely necessary to minimize your costs.

2.Quick and Easy Quotes

Mazak quickly provides you with a free, no obligation quote to repair or rebuild your spindle. Our online quoting tool is quick and easy.

3. Unmatched Parts Inventory and Reconditioning Services

Mazak maintains $65 million in parts inventory – $25 million in unit inventory including ATCs, shifters, tables, and spindles – totaling $90 million in parts and units in Mazak's North American inventory, and 55,000 unique parts including spindles. All spindles parts provided from our Mazak North American Headquarters in Florence, KY are replaced or re-conditioned to original specifications. Our spindle repairs are processed in an ISO: 9001:2008 cleanroom environment and overseen by Mazak highly-meticulous quality control teams. We build all spindles to OEM factory specifications according to factory build procedures to ensure the highest quality standards – every time.

4.Thorough Quality Testing

We inspect and test all spindles fully in clean, climate controlled conditions. During this quality test, spindles are reassembled and balanced before undergoing 12 hours of test stand runoff. Mazak measures spindle bearing temperatures and performs vibration analysis benchmarking to ensure long, reliable spindle life.

5.Fast Turnaround Times

Mazak proudly offers the industry’s fastest turnaround times on new and refurbished spindles with 95 percent shipping same day. We have the stock to support more than 600 different spindle variations to provide you with a cost-effective spindle solution that meets your specifications.

We complete spindle repairs and rebuilds in three to five days and offer same-day shipping on new and refurbished spindles in stock.

Industry's Best Warranty

Industry’s Best and Unparalleled Spindle Warranty

We understand that you depend on your machines to run smoothly, all the time. That’s why we have expanded our Optimum Plus support program to include a 1-year or 4,000-hour warranty on all spindles with Mazak installation provided from our Mazak North American Headquarters in Florence, Kentucky.

This expanded warranty on spindles is part of our Optimum Plus total support program and represents Mazak’s company-wide commitment to providing the best, most comprehensive customer service in the industry. It ensures you are able to maximize the value of your Mazak purchase, gain the best possible competitive advantage as well as keep your Mazak equipment efficiently producing parts at all times.

Rebuilt Spindle Maintenance

Caring for your New Rebuilt Spindle

Smooth production relies on your machine’s spindle performance. Down machine tool spindles and repairs can be avoided through proper maintenance.

Here are seven simple maintenance tips to help keep your operations running smoothly.

1. Lubrication is key to a spindle’s performance and longevity.

Therefore, it’s important to keep your lubricating fluids clean and at safe operating levels. It’s also important to adhere to the machine tool OEM’s recommended lubrication schedule. If you have an air/oil spindle, be sure to service the air-intake filters on a regular basis.

2. Check spindle runout every 6 months and/or after any crash via a ground and calibrated spindle test bar.

Also, monitor your spindle’s spring force with a draw bar pull force test. Pull force is what secures tool holders in the spindle and a sizable drop in force could lead to vibration and runout, which can damage both your spindle and part.

3. Keep a constant watch on spindle vibration levels.

If your machine has built-in vibration sensing technology, don’t ignore any of the triggered alarms. Worn spindle bearings are usually the cause of increased vibration, so be sure to replace them when necessary.

4. Maintain spindle-bearing lubrication.

While closed-unit spindles are typically factory lubricated for life, large spindle headstocks, such as those on big turning machines, need to have their bearings lubricated with oil baths. As such, it’s important to maintain the oil levels of these baths.

5. If you have a high-speed spindle with a cooling system, always make sure the chiller unit is running properly.

A rise in chiller system output temperature usually indicates a spindle problem. If this occurs, a Mazak certified technician can thoroughly check the system.

6. Always re-install any machine covers that have been removed due to routine maintenance or any other reason.

These covers protect the spindle area, keeping contaminants from infiltrating the spindle, spindle motor and other components.

7. When your spindle requires a repair or rebuild, it’s best to have the machine tool OEM perform the services

When your spindle requires a repair or rebuild, it’s best to have the machine tool OEM perform the services to ensure the use of factory-certified parts and that all repairs reflect the equipment’s original specifications.

Mazak offers free technical support regarding recommended maintenance, replacement options and processes.