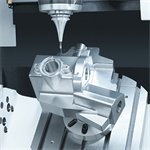

DONE IN ONE

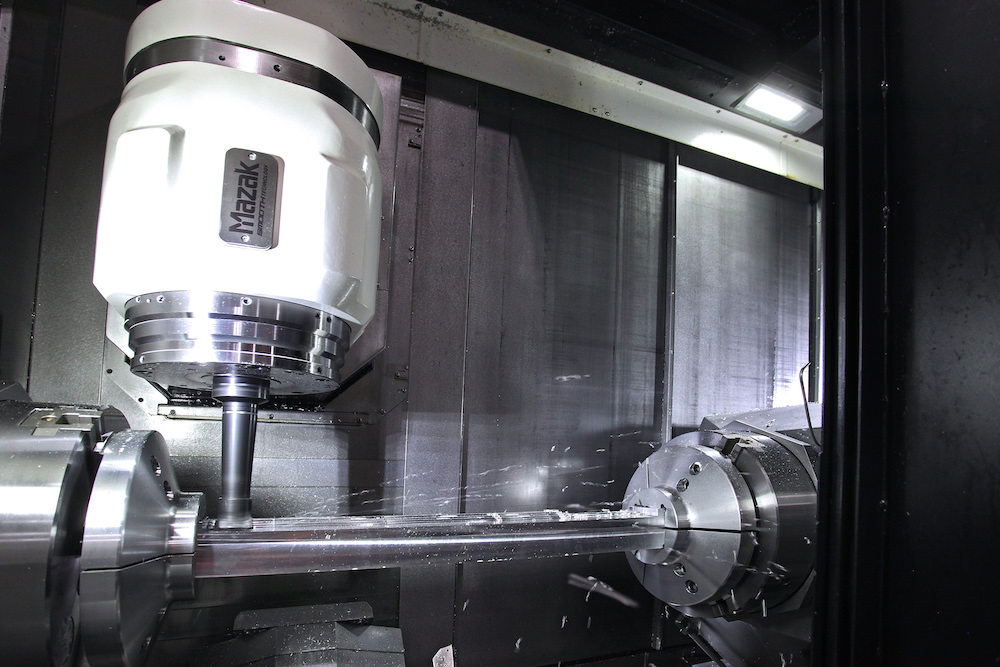

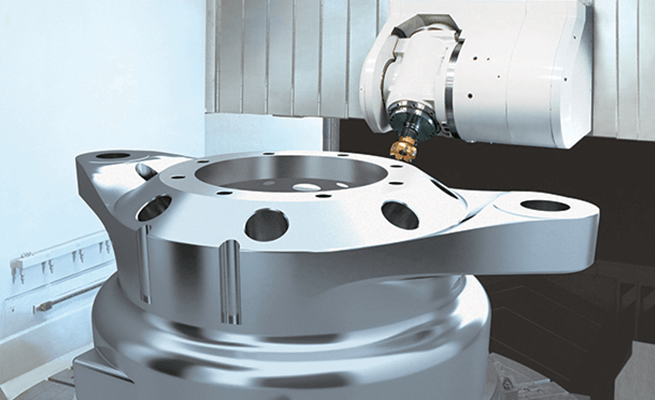

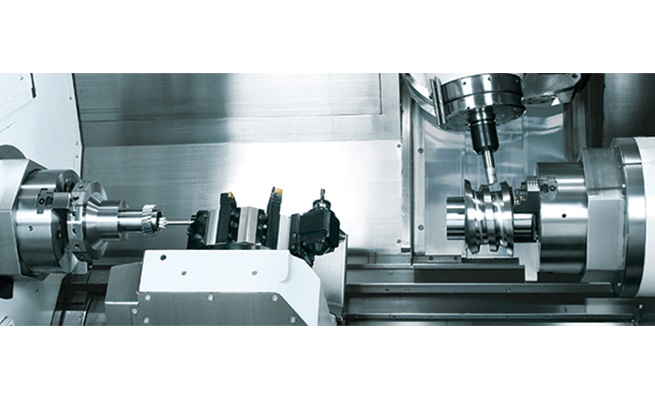

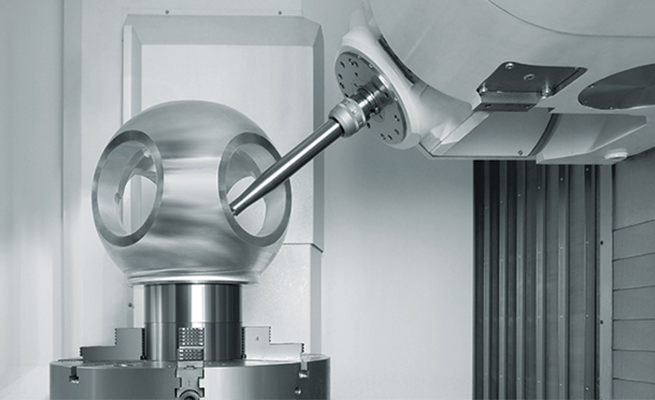

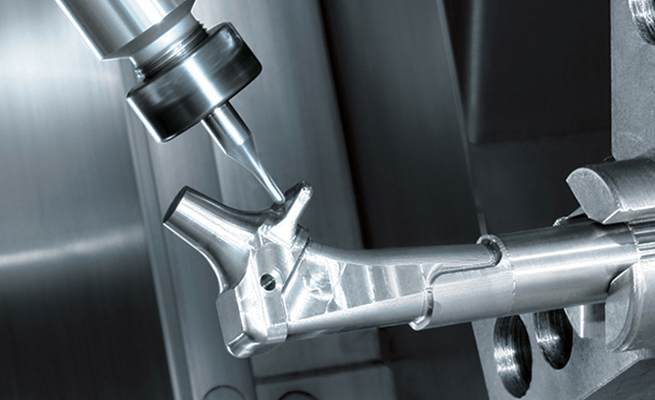

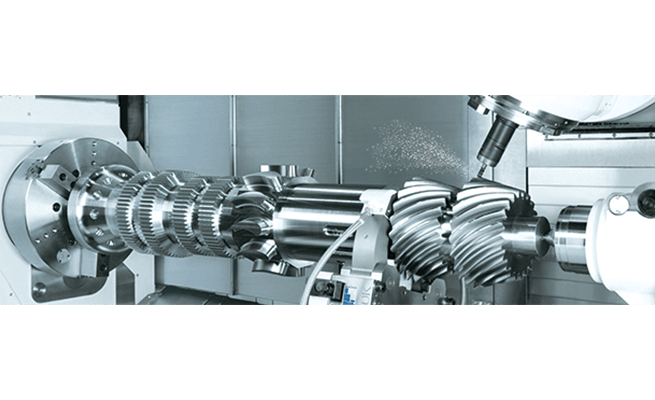

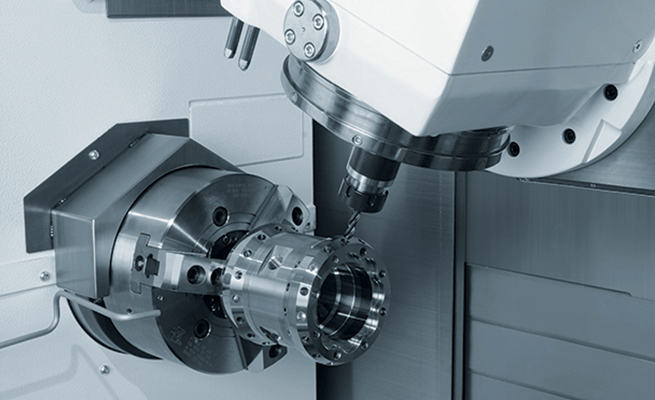

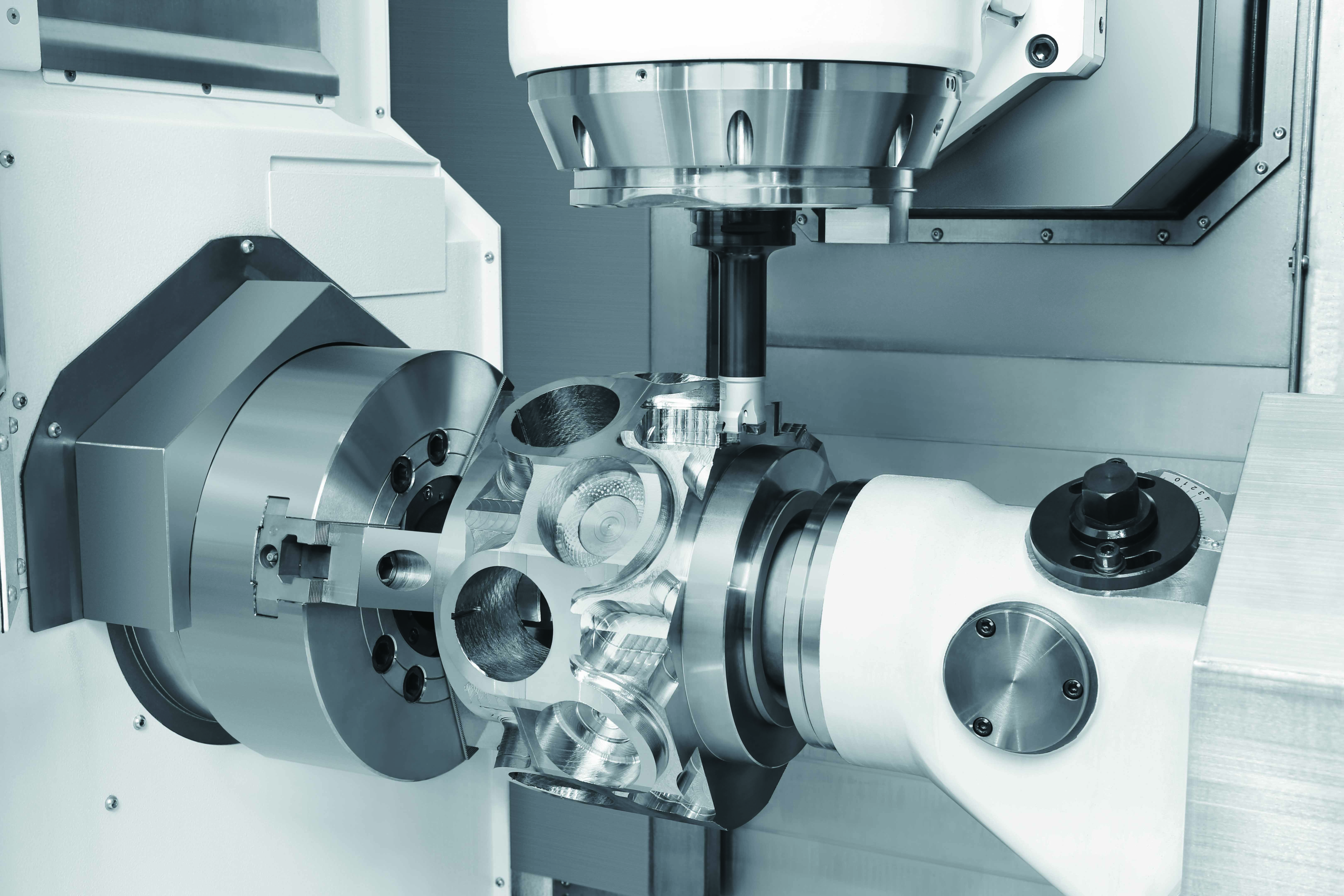

Mazak’s DONE IN ONE® concept incorporates all processes from raw materials input through final machining in just one machine. Achieved with a second turning spindle and a milling turret or with a two-spindle, two-turret configuration, DONE IN ONE machines offer maximum productivity, reduce production lead times, improve machining accuracy and lower operating expenses.

DONE IN ONE Capability:

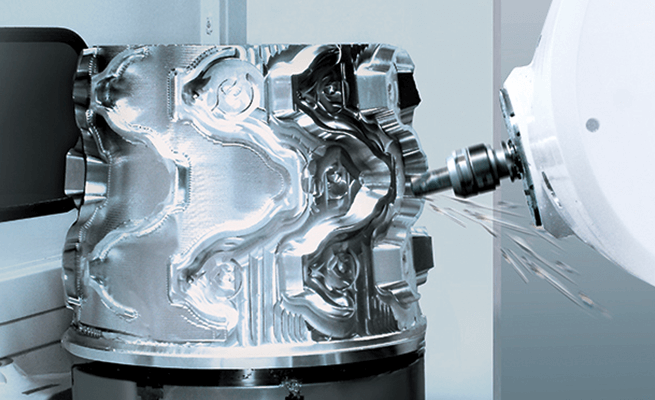

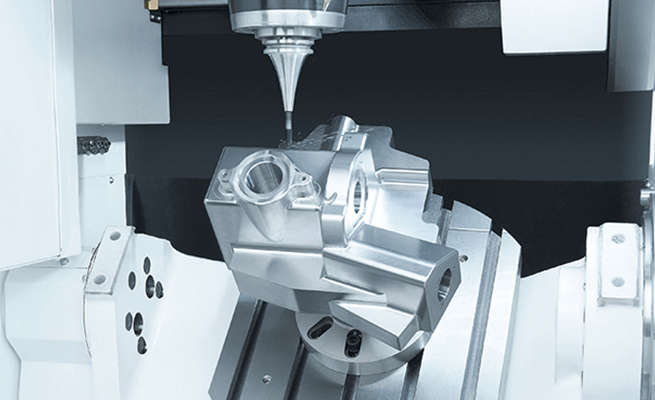

- Increases capacity, flexibility, productivity and profitability

- Improves machining accuracy and overall part quality

- Streamlines production and boosts output with fewer machines and less increases in workforce

- Maximizes use of floor space

- Enhances overall management and enables production of parts on demand

- Reduces part costs via fewer fixtures and less tooling

- Keeps manufacturers competitive