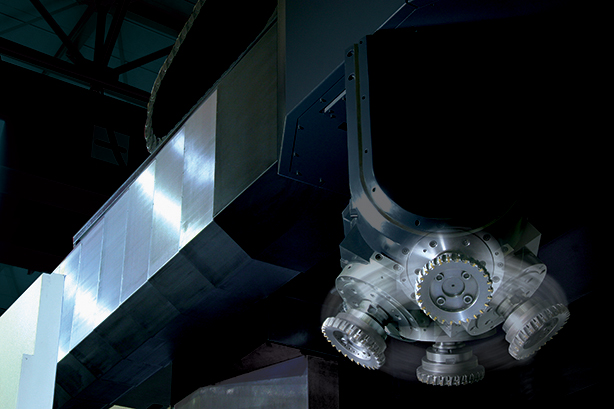

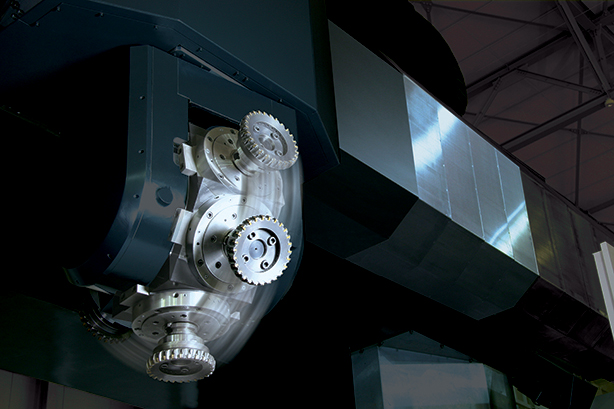

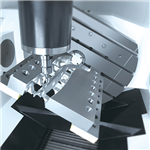

In simultaneous 5-axis machining, the machine tool’s three linear axes (X, Y and Z) and two rotational axes (A and B) all engage at the same time to perform complex processing on parts. With 3 + 2, the machine executes a 3-axis milling program with the cutting tool locked in a tilted position using its two rotational axes. The process, also known as 5-axis positional machining, relies on the fourth and fifth axes to orient the cutting tool in a fixed position rather than manipulate it continuously during the machining process.

5-Axis

What is 5-Axis Machining?

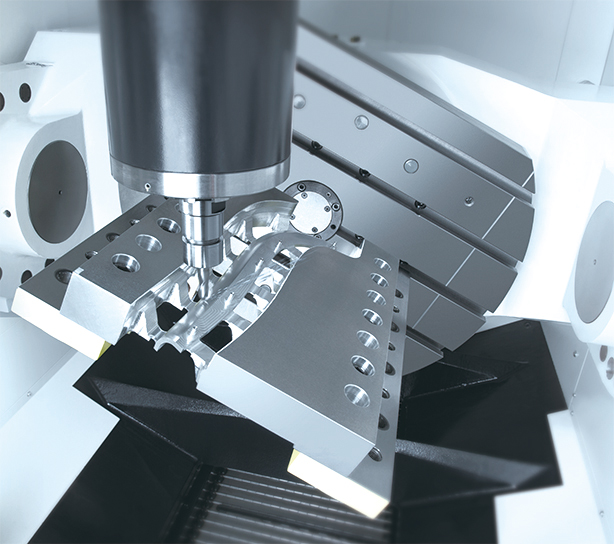

5-axis machining provides infinite possibilities as to the part sizes and shapes you can effectively process. The term “5-axis” refers to the number of directions in which the cutting tool can move. On a 5-axis machining center, the cutting tool moves across the X, Y and Z linear axes as well as rotates on the A and B axes to approach the workpiece from any direction. In other words, you can process five sides of a part in a single setup.

5-AXIS AND MULTI-TASKING MACHINE TOOL SELECTION GUIDE

Simultaneous 5-Axis Machining Versus 3 + 2 Machining

Why Simultaneous 5-Axis?

Our simultaneous 5-axis technology raises the limits on the types of part geometries you can machine. By empowering you to produce highly complex components in a single setup, our 5-axis machines unbridle the imaginations of your engineers and redefine your overall capabilities.

5-Axis Machining Benefits

- Machine complex shapes in a single setup for increased productivity

- Save time and money with less fixture preparation

- Boost throughput and cash flow, while shortening lead times

- Higher part accuracy because the workpiece does not move across multiple workstations

- Ability to use shorter cutting tools for higher cutting speeds and less tool vibrations

- Achieve superior surface finishes and overall better part quality

A 5-Axis Solution for Every Application

We offer the industry’s most advanced and comprehensive selection of 5-axis machine configurations to give you the best cost of ownership as well as endless part-processing capabilities.

Download the 5-Axis Machine Selection Guide

With so many 5-axis options from which to choose, it is important to only invest in the technology and capabilities that apply to your specific applications. To help you identify the most relevant and cost-effective solution for your capital investment, we have developed a 5-Axis Solution selection guide, which takes you through the decision making process in three simple steps.

Contact your local Mazak Representative or visit one of our Technology Centers to identify what Mazak Machining Center best fits your part-processing needs.