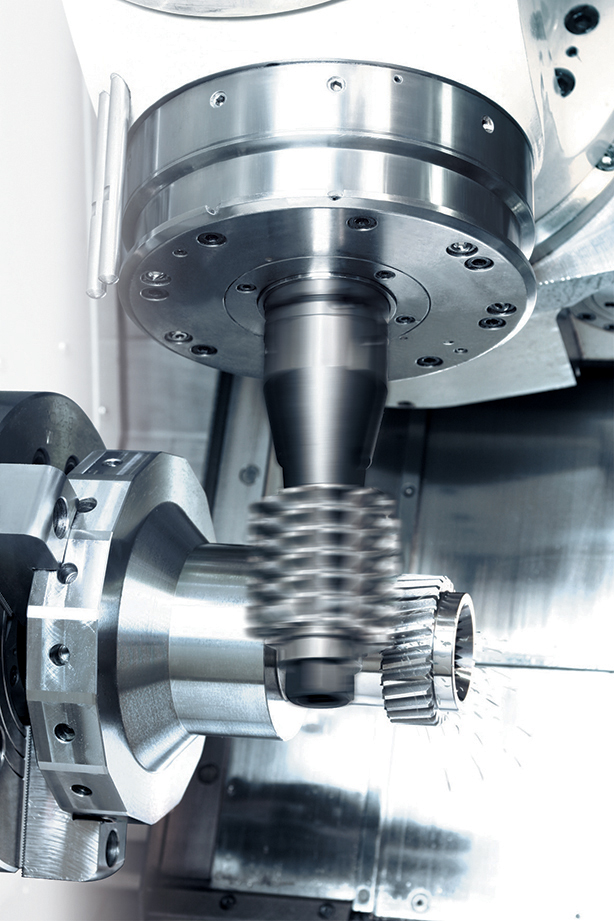

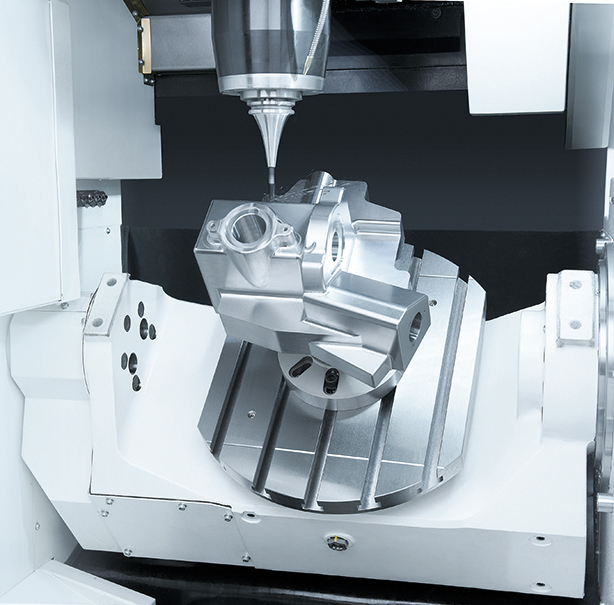

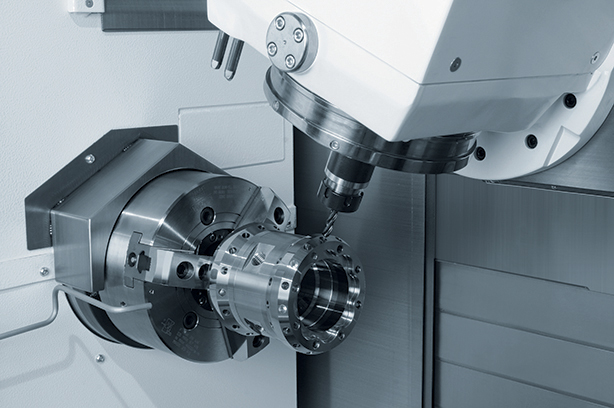

Multi-Tasking is when you combine several cutting processes, including turning, milling, drilling, tapping and deep-hole boring, on one machine as opposed to having those same processes handled by multiple machines.

Multi-Tasking

What is Multi-Tasking?

Mazak Multi-Tasking has revolutionized manufacturing and plays a critical role in today’s factories. Mazak continues to pioneer the machine tool technology that provides single-setup complete part machining, or DONE IN ONE processing from raw material to finished part.

Besides the amazing gains in productivity, Mazak Multi-Tasking technology has catapulted shops, especially smaller ones, to levels where they can easily machine the most complex parts in the world and do so cost-effectively.

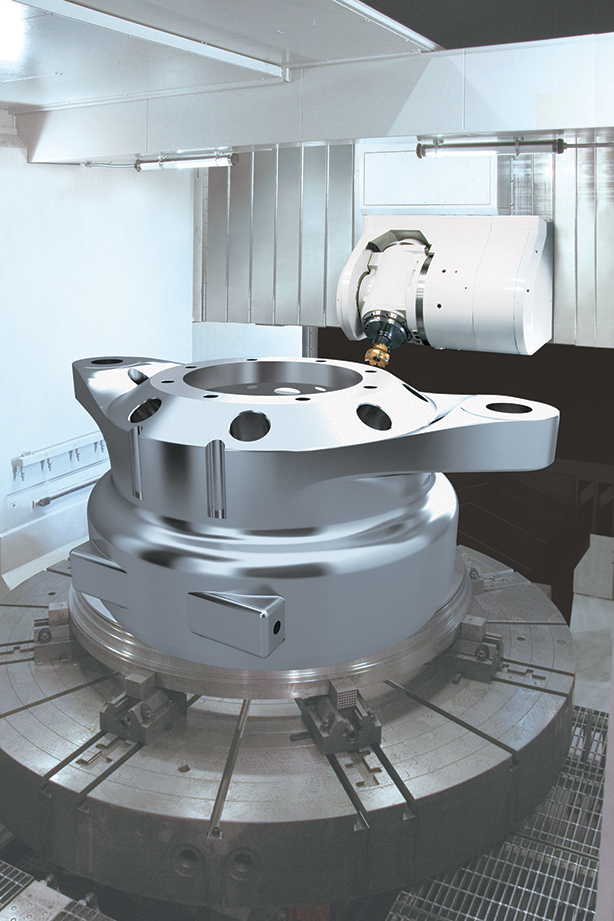

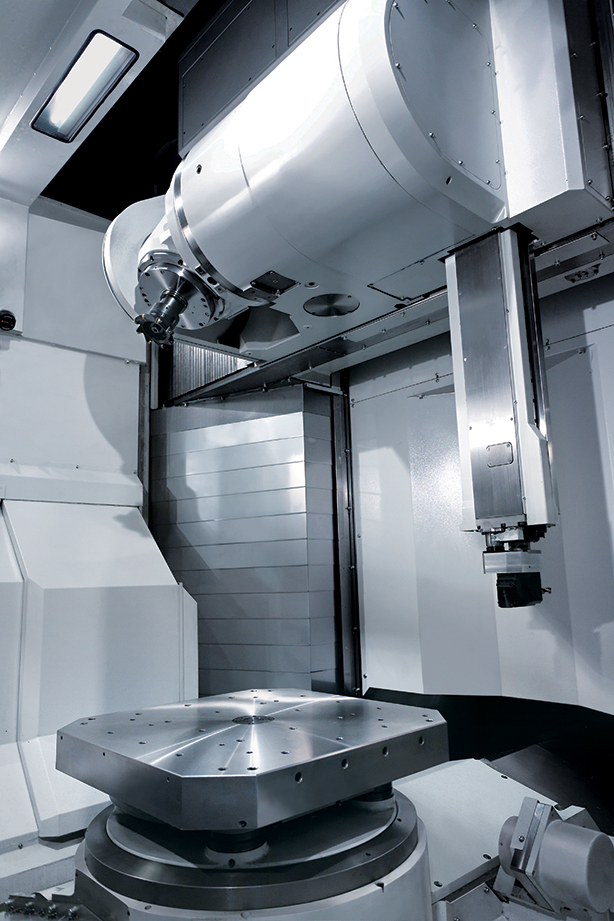

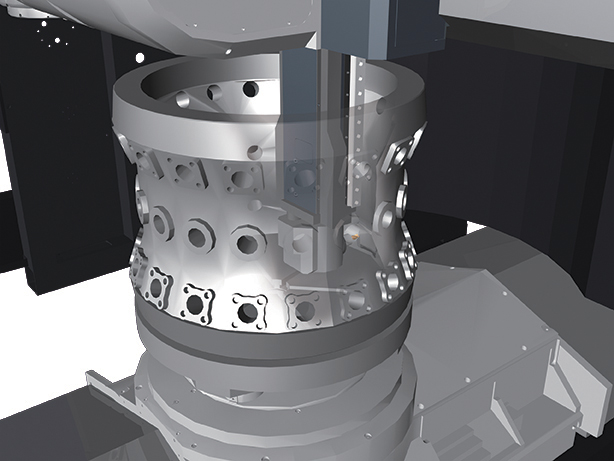

With the industry’s most expansive product range, Mazak Multi-Tasking machine configurations can pack second turning spindles, multiple tool turrets with rotary tool stations, Y-axis off-centerline capability, tilt/rotary B-axis milling spindles, rotary/tilt tables and large capacity tool magazines.

What is Multi-Tasking?

Why Multi-Tasking?

Our Multi-Tasking machines have the ability to mill, turn, drill and hob part features with high accuracy and high quality, while also significantly reducing setup time by performing most or all of a part’s machining in one cycle. Combining operations also reduces inaccuracies that can occur when moving parts across multiple workstations, as well as eliminates work-in-process inventory that might otherwise linger between standalone machine tools. In fact, the benefits of our Multi-Tasking machines are so great, we use them in our own manufacturing facilities to make other Mazaks.

Multi-Tasking Benefits

- Significant reductions in production lead times and part costs

- Improved machining accuracy and overall part quality

- Increased capacity, flexibility, productivity and profitability

- Improved cash flow by producing parts on demand

- Cost benefits such as reduced part costs via fewer fixtures, tools and labor requirements

- Increased cutting times, but not labor costs

- Added floor space by doing more using less machines

- Automatic load/unload integrated with machining cycle for unattended operation

- Large companies and OEMs achieve shorter payment cycles, increased throughput and more

- Job shops and contractors gain a more profitable pricing structure and several other benefits

- Multi-Tasking helps keep manufacturing work in North America as opposed to being offshored

A Multi-Tasking Solution for Every Application

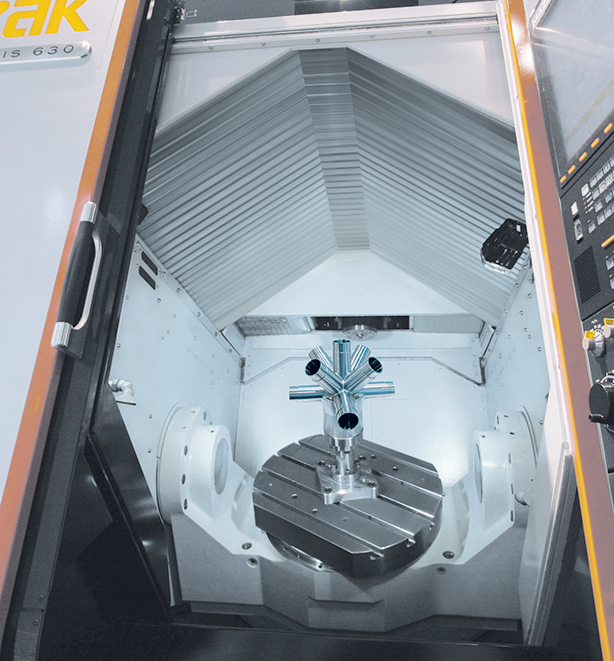

Whether you are producing small parts with unit cycle times of under a minute or large, complex components that require a full week of machining, we have a Multi-Tasking solution to increase your efficiency, flexibility and productivity. In fact, with more than 90 configurations from which to choose, we offer the largest selection of advanced, highly versatile Multi-Tasking models in the world to ensure the lowest cost of ownership.

Why Mazak Multi-Tasking? Find Out On This Infographic

Mazak Multi-Tasking Machine Finder

Contact your local Mazak Representative or visit one of our Technology Centers to identify what Mazak Machining Center best fits your part-processing needs.