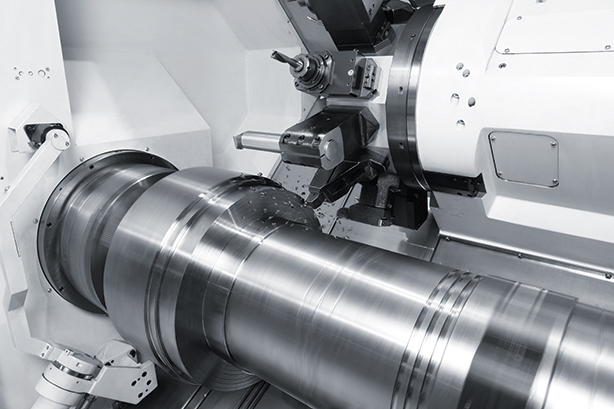

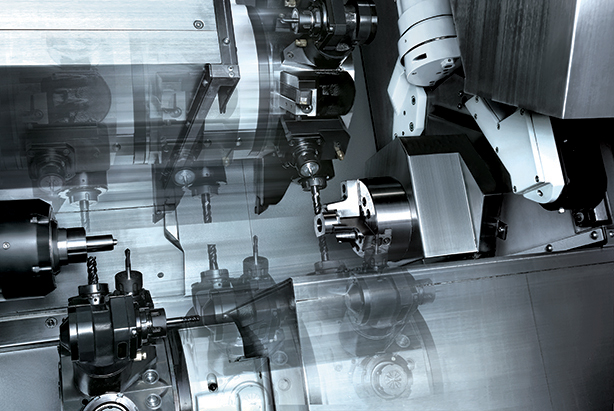

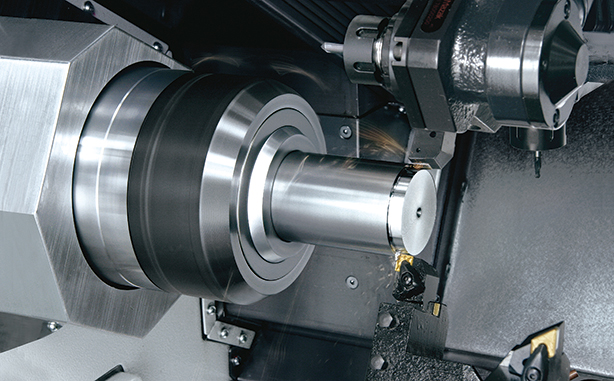

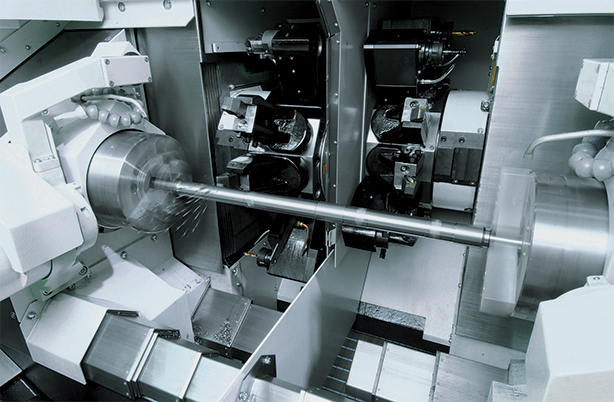

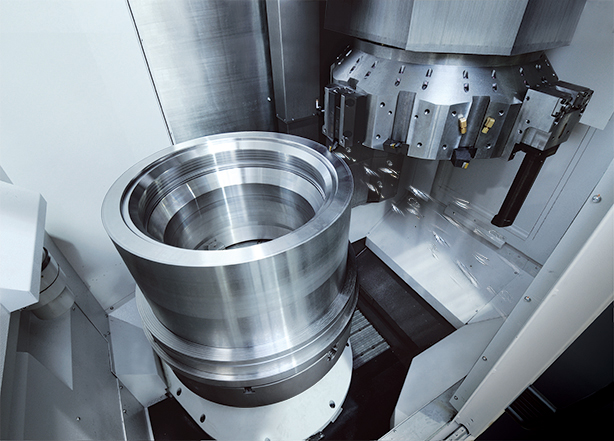

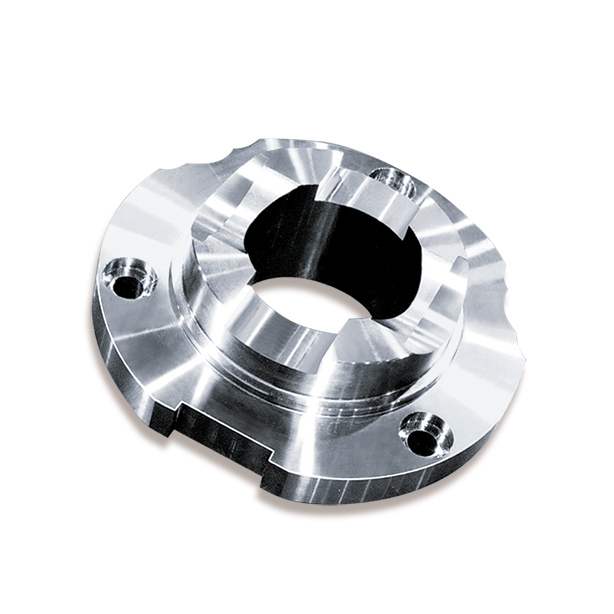

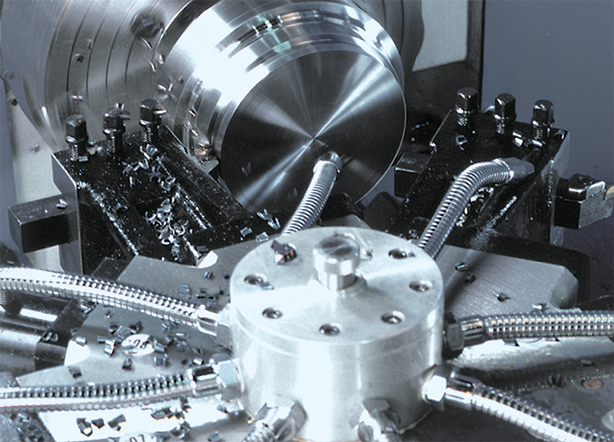

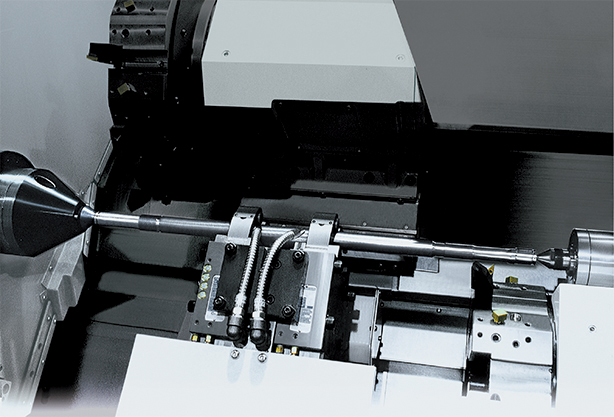

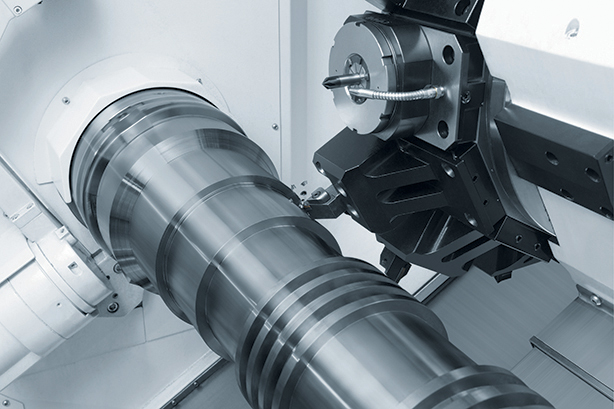

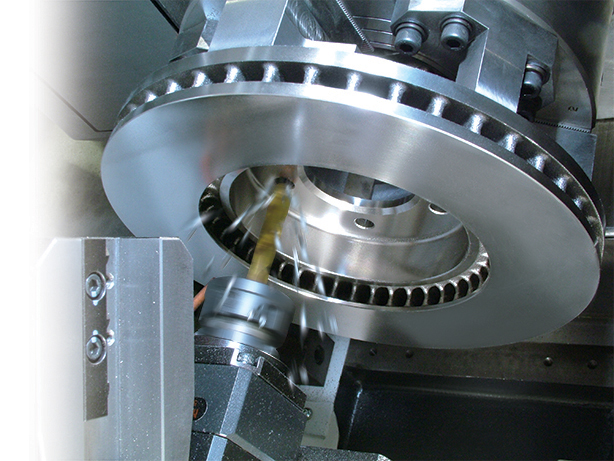

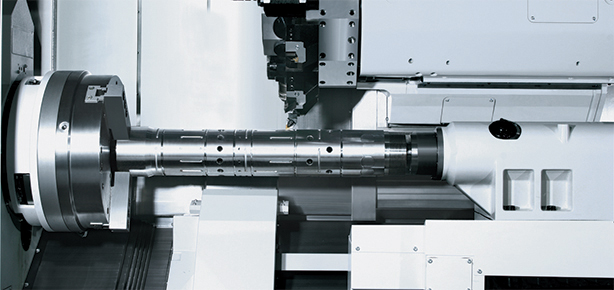

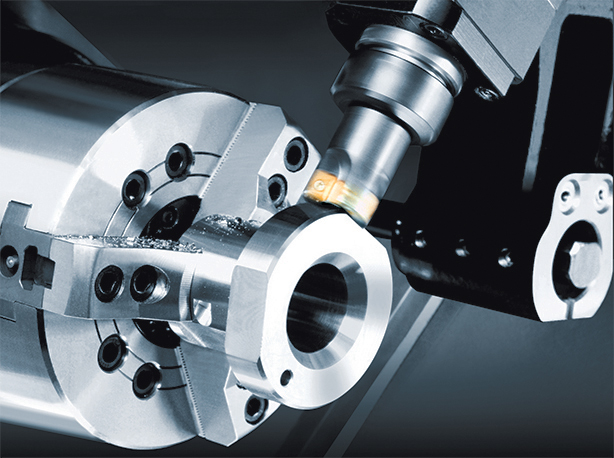

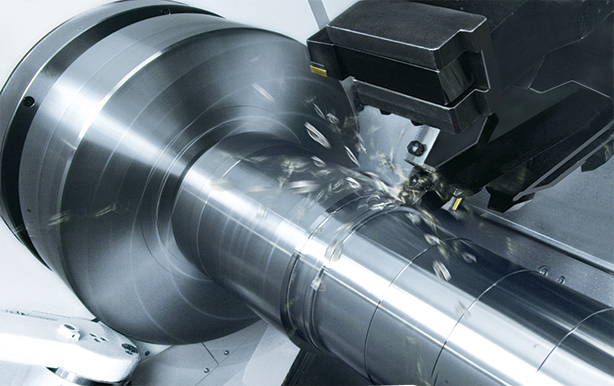

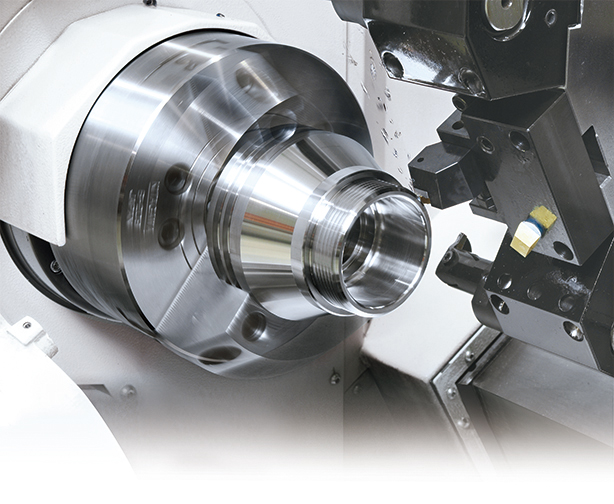

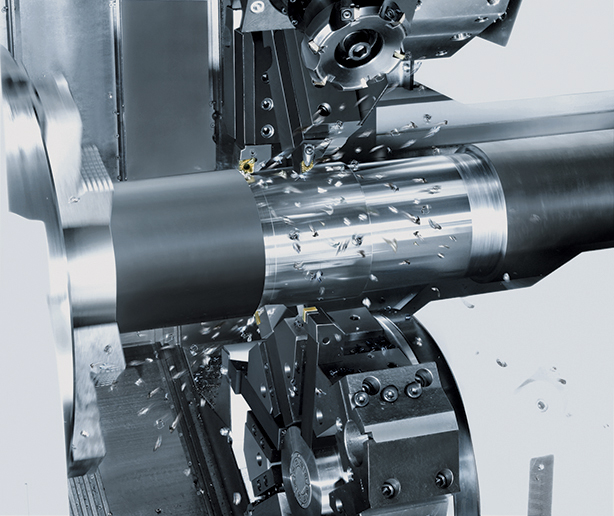

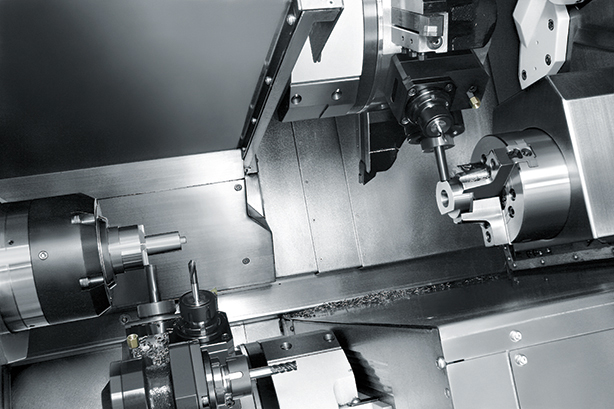

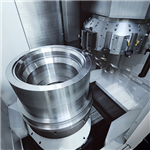

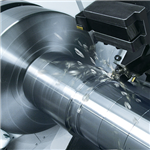

While our CNC turning centers range in size and capacity, from two-axis models to machines with rotary tool spindles and second spindles, we design each one with quality, reliability, ease of operation and safety in mind. Furthermore, thanks to our Production-On-Demand manufacturing philosophy, all of our turning centers incorporate the latest, most advanced turning technology for boosting your productivity and growing your business.

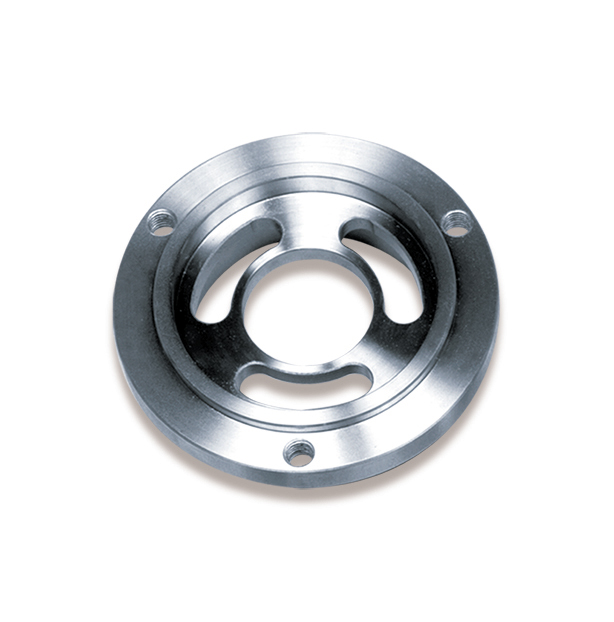

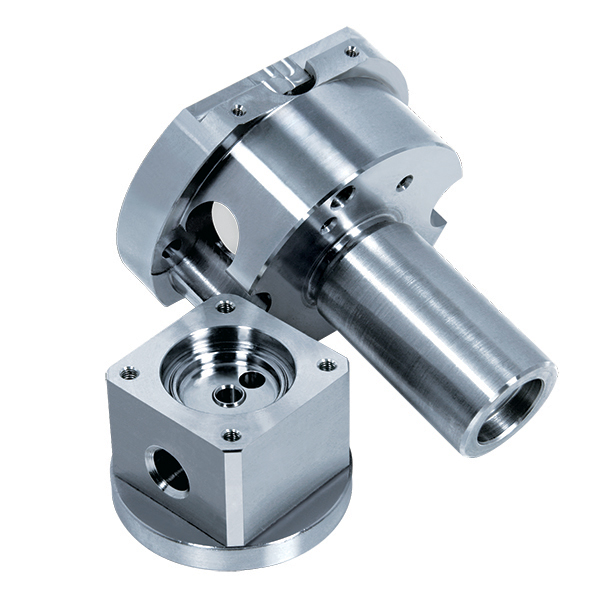

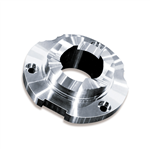

Our MAZATROL programming language has its developmental roots in our turning machines. For the ability to handle simple parts to those that are complex and require 4-axis turning operations, MAZATROL gives you the versatility to program those parts using either conversational programming or G-code programming (EIA/ISO) — or even a combination of the two programming types.

Thanks to our Production-On-Demand manufacturing philosophy, all of our turning centers incorporate the latest, most advanced turning technology for boosting your productivity and growing your business.