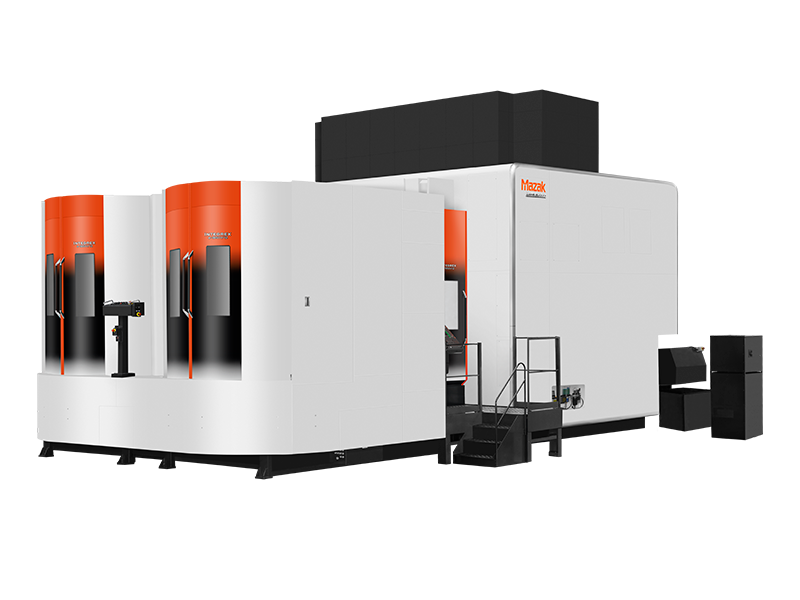

INTEGREX e-1850V/12

MACHINE DESCRIPTION:

The INTEGREX e-1850V/12 Multi-Tasking machine combines full 5-axis machining, vertical turning operations and pallet-changing capabilities to productively process large, highly complex parts from a variety of workpiece materials.

Because the machine is able to perform milling, turning, boring and drilling operations in single setups, manufacturers can reduce the inaccuracies that occur when moving heavy parts across multiple workstations, eliminate work-in-process inventory and boost overall throughput.

High-speed and high-torque milling spindle specifications are available to successfully meet a broad range of application requirements in industries such as aerospace, heavy construction and energy.

The machine comes with a two-pallet changer that provides unattended operations and off-cycle part setup. This simple, efficient form of automation allows operators to load, unload and inspect parts on one pallet while the machine works on the other undisturbed.

MACHINE CHARACTERISTICS:

- Handles parts up to 92.52" in diameter and 70.87" long

- Spindle selection addresses various metal removal requirements

- Tilting B-axis allows for full 5-axis machining

- Powerful turning spindle delivers heavy-duty performance

- Tool storage capacities up to 348 tools offer high flexibility

- Large, heavy-duty pallets handle high part weight capacities

- Two-pallet changer facilitates unattended machining

- Integrates with optional PALLETECH System for lights-out operations

Machine Specifications

| Specification | Bed Length - | |

|---|---|---|

| Capacity | Maximum Machining Diameter | 92.520 in / 2350 mm | Maximum Machining Length | 70.870 in / 1800 mm |

| Turning Spindle | Chuck Size | 65 in / 1650 mm |

| Maximum Speed | 250 rpm | |

| Milling Spindle | B-Axis Travel | 150° |

| Magazine Capacity | 40 | |

| Maximum Speed | 10000 rpm | |

| Feed Axes | Travel (X Axis) | 120.28 in / 3055 mm |

| Travel (Y Axis) | 72.83 in / 1850 mm | |

| Travel (Z Axis) | 70.87 in / 1800 mm | |