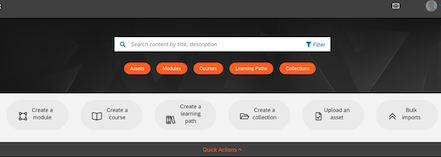

Mazak Spindle & Unit Rebuild Program

Spindle performance rules part production. When your spindles are up and running, you're cutting parts and making money. Mazak’s spindle unit rebuild and repair program leverages 30 years of spindle rebuild expertise to help you make the most of every minute in your production cycle. We’re so confident in our spindles’ performance that we offer the industry’s best warranty on our work.

Call us at: 888-462-9251 (Option 2).

| Spindle Repair/Rebuild Process | Get an online quote Now |

Mazak Spindle Services by the Numbers:

Spindle Variations

More than 700 spindle variations in our fully stocked inventory.

Shipping

97% same day shipping for parts and new or refurbished spindles.

Turnaround Time

We complete repairs/rebuilds within 3-5 days after we receive your spindle.

Testing

Every repaired and rebuilt spindle receives 12 hours of test-stand runoff and vibration benchmarking.

Warranty

1-year or 4,000-hour warranty on rebuilt spindles with Mazak-certified installation.

Precision

Our precision measurement tools ensure that we meet all factory specifications.

Spindle Inventory

More than $54 million in globally available dedicated spindle inventory.

ISO 9001:2015

We process spindle repairs in a clean-room environment overseen by quality control teams with ISO 9001:2015 certification.

Download our spindle services brochure

Spindle Service Options

Spindle Service Options

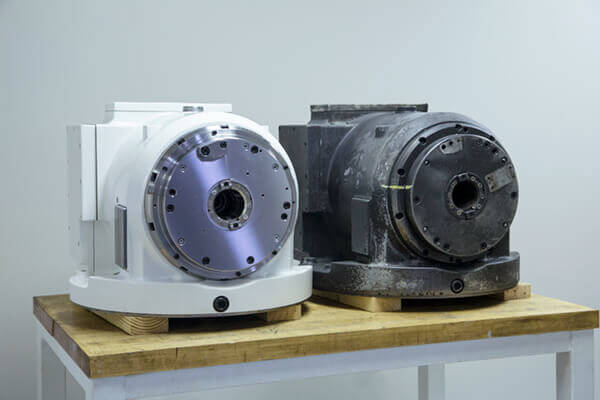

Mazak’s certified Spindle Repair/Rebuild Department offers the highest-quality complete, reliable spindle repair, rebuild (partial/complete) and replacement services for all Mazak spindles. Our services include turning centers, vertical and horizontal machining centers, Multi-Tasking and 5-axis machines.

We also offer the highest-quality new and remanufactured index tables, ATC shifters, gearboxes, live tooling and milling turrets.

The Mazak Spindle Repair/Rebuild Process

The Industry's Best Spindle Repair/Rebuild Process

Mazak’s comprehensive spindle repair/rebuild process ensures that your spindle stays up and running, reliably, through every cycle. We test each spindle rigorously, and our certified technicians perform meticulous service to ensure that every spindle meets factory specifications when it leaves our facility.

1. Comprehensive Initial Spindle Inspection and Failure Analysis

We conduct a thorough analysis to determine the root cause of spindle failure. Next, we examine all spindle components for signs of wear, improper fit and size. To minimize your costs, we only replace components that absolutely require it.

2. Quick and Easy Quotes

Use our quick, easy online tool to receive a free, no-obligation quote to repair or rebuild your spindle.

3. Unmatched Parts Inventory and Reconditioning Services

Mazak maintains $65 million in parts inventory and $25 million in unit inventory, including ATCs, shifters, tables, and spindles, totaling $178 million in parts and units in Mazak's North American inventory. All the spindle parts we provide from our Mazak North American Headquarters in Florence, KY are replaced or reconditioned to original specifications. Our spindle repairs are processed in an ISO 9001:2015 clean-room environment and overseen by Mazak meticulous quality control teams. We rebuild all spindles to OEM factory specifications and follow factory build procedures to ensure the highest quality standards – every time.

4. Thorough Quality Testing

We inspect and test all spindles fully in clean, climate-controlled conditions. During this quality test, we reassemble and balance spindles before they undergo 12 hours of test-stand runoff. We measure spindle bearing temperatures and perform vibration-analysis benchmarking to ensure long, reliable spindle life.

5. Fast Turnaround Times

Mazak proudly offers the industry’s fastest turnaround times on new and refurbished spindles, with 97% shipping same day. Our stock supports 700 different spindle variations to provide you with a cost-effective solution that meets your needs.

We complete spindle repairs and rebuilds in 3-5 days, and offer same-day shipping on in-stock new and refurbished spindles.

Industry's Best Warranty

The Best Spindle Warranty in the Industry

We understand that you depend on your machines to run smoothly all the time. That’s why we include a 1-year or 4,000-hour warranty on all spindles with Mazak installation provided from our Mazak North American Headquarters in Florence, Kentucky.

This expanded warranty on spindles is part of our MPower complete customer care and represents Mazak’s company-wide commitment to providing the industry's best, most comprehensive service. We ensure that you can maximize the value of your Mazak purchase, gain the best possible competitive advantage and keep your Mazak equipment efficiently producing parts at all times.

Spindle Support

Your spindle is the heart of your machine tool, and if it needs service, we have the ISO certified repair/rebuild capabilities you need, with quick turnaround and thorough results.

Spindle Repair/

Rebuild Process

Our Spindle Rebuild Center turns around repairs or rebuilds within 3-5 days, including runoff, benchmarking and a 1-year or 4,000-hour warranty.

Keep your spindles on task

Spindle Maintenance

Order a new or refurbished spindle, and your order ships the same day 95% of the time. Our parts inventory supports more than 600 spindle variations.

Receive replacement spindles fastSpindle Repair/Rebuild Process

Mazak's comprehensive spindle repair/rebuild process ensures that your spindle stays up and running, reliably, through every cycle.

Learn more